Natural sand is produced by natural forces, such as river sand, sea sand, and mountain sand.

Natural Sand

Generally, mountain sand is more weathered, containing more mud, organic impurities and light substances. Sea sand often contains shells and other impurities, and its components such as the chlorine, sulfate and magnesium salts may cause corrosion of steel bars. All the components will affect the performance of concrete.

Therefore, the quality of river sand is the best and suitable for construction among natural sand.

River sand is a kind of non-metallic ore with complex composition and smooth surface that generated by repeated collided and rubbing in water for a long time in a natural stone state. River sand particles are smooth, relatively clean and with wide source.

River Sand Production Line

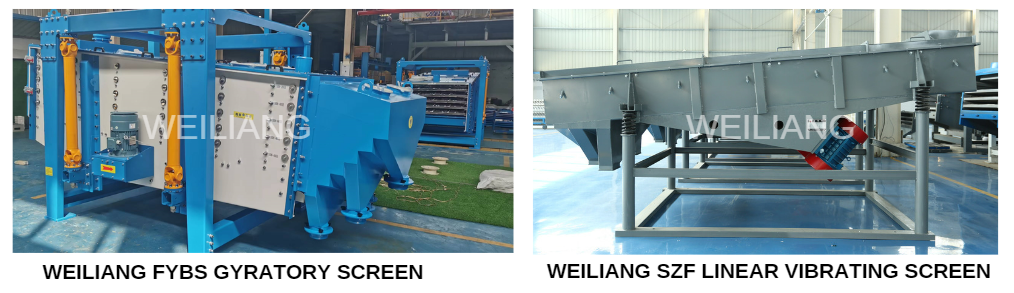

The river sand production line is different from the artificial sand production line, it has no crushing step. River sand is usually washed in water at the front for cleaning and coarse screening purposes. The wet sand is conveyed evenly into the sand drying system to remove the moisture content of the sand. The dry sand is then conveyed to a WEILIANG SZF LINEAR VIBRATING SCREEN for coarse screening and then evenly to a WEILIANG FYBS GYRATORY SCREEN for fine screening to get the desired size.

Linear screens are not always necessary, we have some customers who only use gyratory screens for sieving on site, depending on the characteristics of the sand.

What Do We Offer

Screening system in sand production line

Artificial Sand

Artificial sand also called manufactured sand or crushed sand or mechanical sand, manufactured by crushing rocks, stones or larger aggregates into small size particles in the quarry.

It is processed by mechanical crushing and sieving with consistency to be used as a substitute for river sand.

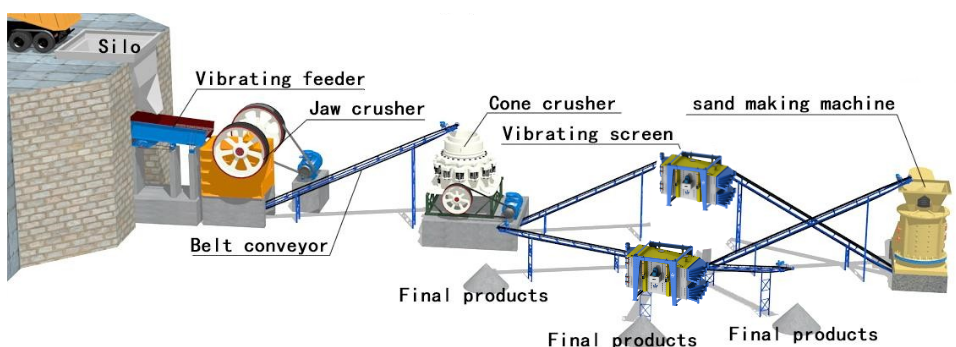

Artificial Sand Production Line

Artificial sand production lines are divided into dry sand production line and wet sand production line, which are distinguished by sand washing systems.

Artificial sand making production line usually consists of vibrating feeder, primary crusher (jaw crusher), secondary crusher (impact crusher), sand making machine, vibrating screen, sand washing machine, belt conveyor system, centralized electric control box and other equipment. The configuration can be altered accordingly.

Dry Artificial Sand Production Line

The vibrating feeder feeds the stone evenly into coarse crushing machines (jaw crusher) for primary crushing. And then the crushed stone is conveyed to the fine crushing machines (impact crusher or cone crusher) through belt conveyor for secondary crushing.

The material produced by impact crusher needs to be further processed by sand making machine to proceed the finest-crushing stage. The finely crushed material is then screened into coarse sand, medium sand, fine sand and other specifications by WEILIANG FYBS VIBRATING SCREEN.

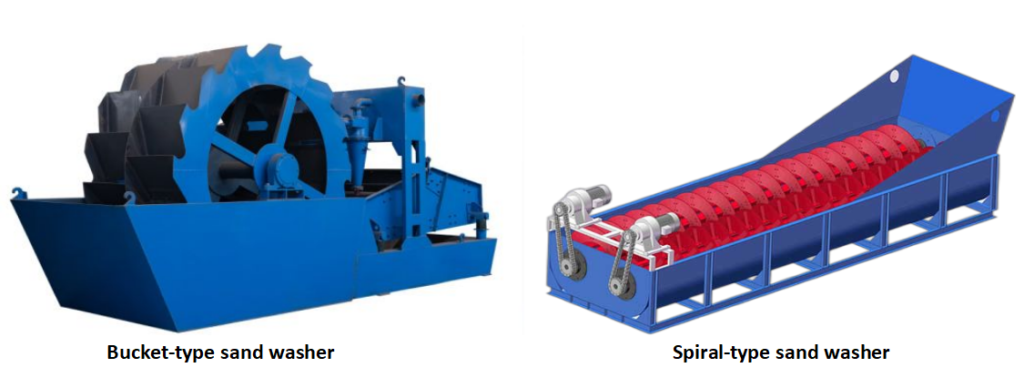

Wet Artificial Sand Production Line

Water is involved in the entire sand and gravel aggregate production process as the working medium and dust suppression measure of the wet sand production line.

The upstream of the wet process line is the same as the dry process. The material from vibrating screen is sent to the sand washing machine by the belt conveyor to remove dirt, dust, and other impurities. And the sewage discharged from sand washing machine can be recycled by fine sand recovery plant.

During the sand making process, the oversized particles are returned to the sand making machine to be reshaped into smaller particles and then sent to the vibrating screen again for screening, thus forming a closed circuit for multiple cycles.

What Do We Offer

Rectangular Wet Screen in Wet Sand Processing

Sand Sieving Projects

Weiliang has rich experience in the field of screening in the sand making industry, and has cooperated with more than 100 companies. For example, a company in Inner Mongolia purchased over 200 FYBS gyratory screen to sieve sand, and a company in Xinjiang purchased 30+ sets at one time. Customers are located in Hunan, Shandong, Zhejiang, Shanxi, Xinjiang, Sichuan, Ningxia etc in China, a total of thousands of FYBS gyratory screen have been sold.

Cases Share

1. Meng** COMPANY CASE

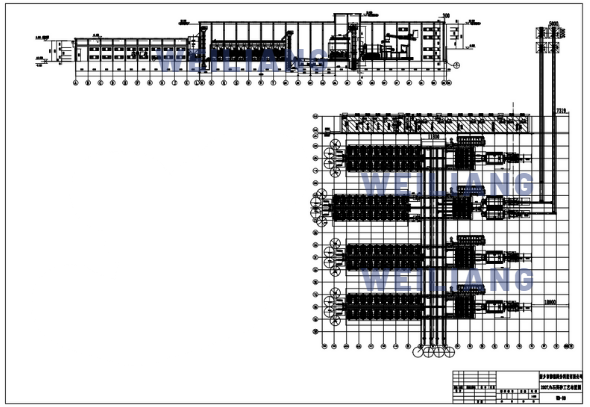

Foundry Sand Production Line (EPC project)

The whole line includes drying, conveying, screening, and packaging, with automatic control system.

2. Run** COMPANY CASE

Frac Sand Production Line (EPC project)

Model:

SZF linear vibrating screen for coarse sieving.

FYBS gyratory screen for classification.

Quantity:

SZF-1240-2S 1 set

FYBS-2036-10S 8 sets

Processing Capacity:

50T/H total

Weiliang is responsible for designing complete production lines for our customers, including drying, conveying and screening, which provide the perfect solution.

After the first line was successfully established, it received good feedbacks from the customer and the second line was launched after six months.

3. Chang** COMPANY CASE

Frac Sand Production Line (EPC project)

- The company is the largest frac sand manufacturer in this region with five production lines, the largest one with 50+ sets of FYBS gyratory screens.

- Nearly 200 sets of FYBS gyratory screen have been sold to this company.

- A single set of model FYBS-2036-10S can reach 15 tons per hour.

4. Ju** COMPANY CASE

Frac Sand Production Line (EPC project)——under construction

- Totally four lines, the capacity of a single line is 200 tons per hour

- FYBS-2036-10S:88 sets

- SZF-1236-2S:32 sets

Additional Information

The Differences Between Artificial Sand and Natural Sand

| Artificial Sand | River Sand | |

| Source | It is produced from rock stones. | Naturally available in the riverbank. |

| Silt Content | In M sand the possibility of silt content is less than 2% | 5% to 10% of silt particles available in sand. |

| Moisture Content | oisture content available only when the sand is washed by water. | Naturally moisture content is available. |

| Surface Gravity | 2.5 to 2.9 depends on parent rock. | 2.3 to 2.7 depends on rocks in catchment area. |

| Size of Material | No oversize particles since it are artificially manufactured. | The oversize particles are more than 5% available. |

| Quality | We can expect a good quality of material since it is produced from a factory. | The possibility of quality is low because sometimes other types of sand can be mixed with River Sand. |

| Cost | It is manufactured from available rock stone so the price is low. It can be produced near to the construction by the raw material. | Due to the lack of availability, price of river sand is high. |

| Workability | Due to the cubical shape & rough texture, put little strain while mixing with other ingredients. | Due to the smoothness of sand mixing with other materials, easy to compare with M sand. |

| Application | highly recommended for RCC works, brick work & block work. | It can be used for RCC, plastering & filler material etc. |

| Impact on Environment | Less impact on the environment as compared to Sand. | Excavation of River Sand will reduce the groundwater level. |