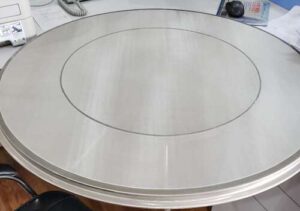

Classic Round Vibrating Screen

No-tools intelligence adjustment device for quick adjusting the excitation force: top force wheel for the horizontal excitation force and bottom force wheel for vertical excitation force.

Qucik-release clamp ring for fast replacement of screen, and the whole screen-replacement only takes 3-5 minutes.