What is Aluminium Oxide (Alumina)?

Aluminium oxide (or Aluminium(III) oxide) is a chemical compound of aluminium and oxygen with the chemical formula Al2O3. It is commonly called alumina and may also be called aloxide, aloxite, or alundum in various forms and applications. It occurs naturally in the mineral corundum in its crystalline polymorphic phase α-Al2O3, the variety that forms the precious gemstones ruby and sapphire. Aluminium oxide is important in the production of metallic aluminium, used as an abrasive because of its hardness and as a refractory material because of its high melting point.

Aluminium is the most naturally abundant type of metal on our planet and it is commonly found in the form of aluminium oxide or bauxite. This variety forms once aluminium is exposed to air, which creates a thin surface layer on aluminium that makes it resistant to corrosion.

Aluminium oxide is an insoluble compound of aluminium. This absence of acute toxicity apart from skin irritation, and general slight chronic toxicity of aluminium oxide is one aspect of what makes this compound a suitable and most common choice in production of advanced ceramics.

What Can Aluminium Oxide Be Used For?

Aluminium oxide, one of the most widespread technical ceramic materials, is used in the production of a wide range of components for many industries. Its main applications are in the following areas:

| 1. Gemstone Industry: Aluminium oxide is used in the formation of sapphires and rubies. In its crystalline form, or corundum, alumina is the basic element in the creation of these two precious stones. |

| 2. Medical Industry: Medical industry: Aluminum oxide is a suitable material for a variety of medical applications, including bionic implants, tissue reinforcement, prosthesis, hip replacement bearings, etc. This is due to the chemical properties of aluminum oxide as well as to its hardness and bio-inertness. |

| 3. Electrical Industry: Aluminum oxide is a fantastic material to use in the production of electrical insulators and high-temperature furnace insulation due to its high melting and boiling points. It is also widely used in the microchip industry. |

| 4. Protective Equipment: Aluminum oxide is an excellent material to use to enhance body and vehicle armor, as well as to manufacture synthetic-sapphire bulletproof ballistics and windows because of its strength and light weight. |

| 5. Industrial Application: Since aluminum oxide is chemically inert, it is the ideal filler for heavy clayware, plastics, and bricks. It is also frequently used as the abrasive part of sandpaper and as an economical alternative to industrial diamonds. |

| 6. Other applications: –Aluminium oxide is used in cosmetics such as blush, lipstick, and nail polish. –Aluminosilicate glass is a commonly used type of glass that often contains 5% to 10% alumina. –Aluminium oxide serves as a catalyst support for many industrial catalysts, such as those used in hydrodesulfurization and some Ziegler–Natta polymerizations. –Aluminium oxide is widely used to remove water from gas streams. –Aluminium oxide flakes are used in paint for reflective decorative effects, such as in the automotive or cosmetic industries. –Insulation for high-temperature furnaces is often manufactured from aluminium oxide. –Small pieces of aluminium oxide are often used as boiling chips in chemistry. –It is used to make spark plug insulators. –Using a plasma spray process and mixed with titania, it is coated onto the braking surface of some bicycle rims to provide abrasion and wear resistance. –In its finest powdered (white) form, called Diamantine, aluminium oxide is used as a superior polishing abrasive in watchmaking and clockmaking. –Aluminium oxide is also used in the coating of stanchions in the motorcross and mountainbike industry. This coating is combined with molybdenumdisulfate to provide long term lubrication of the surface. |

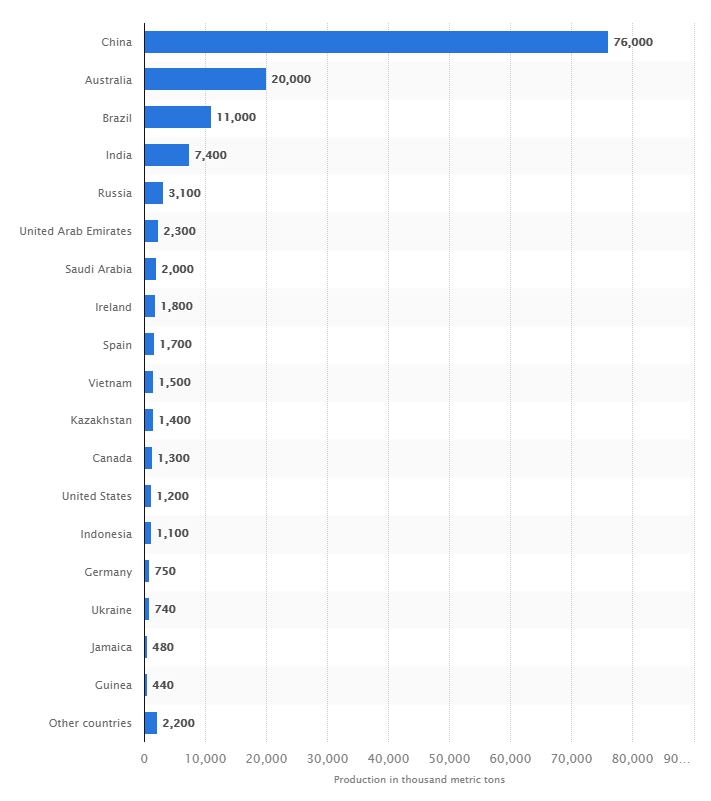

World Alumina Production in 2022, by Country

According to the report published by M. Garside in 2022, China generated over 76 million metric tons of alumina in 2022, compared to Australia’s 20 million metric tons.

Production Process

Alumina is the common name for aluminum(III) oxide. It is used to produce aluminum metal. Traditional primary aluminum production consists of three processes that are independent of each other (Metal World, 2018):

- Bauxite mining,

- Production of alumina from bauxite ores by Bayer Process

- Production of metallic aluminum by electrochemistry by Hall-Héroult process

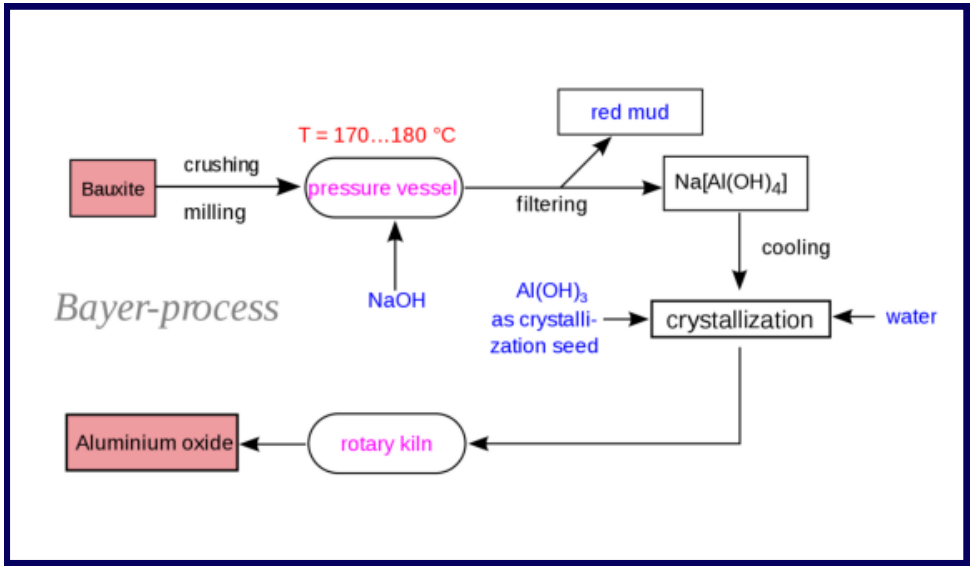

Bayer Process to Produce Aluminium Oxide (Alumina)

The Bayer process is the principal industrial means of refining bauxite to produce alumina (aluminium oxide) and was developed by Carl Josef Bayer. The basic principle is to convert aluminium hydroxide to sodium aluminate using a concentrated sodium hydroxide solution. The aluminium hydroxide is re-precipitated by diluting and adding aluminium hydroxide crystals and the remaining sodium hydroxide solution is re-used to treat the next batch of bauxite, enabling continuous production.

Bauxite, the most important ore of aluminium, contains only 30–60% aluminium oxide (Al2O3), the rest being a mixture of silica, various iron oxides, and titanium dioxide. The aluminium oxide must be further purified before it can be refined into aluminium metal. In the Bayer process, bauxite ore is heated in a pressure vessel along with a sodium hydroxide solution (caustic soda) at a temperature of 150 to 200 °C. At these temperatures, the aluminium is dissolved as sodium aluminate (primarily [Al(OH)4]−) in an extraction process. After separation of the residue by filtering, gibbsite is precipitated when the liquid is cooled and then seeded with fine-grained aluminium hydroxide crystals from previous extractions. The precipitation may take several days without addition of seed crystals.

Over 90% (95-96%) of the aluminium oxide produced is used in the Hall–Héroult process to produce aluminium.

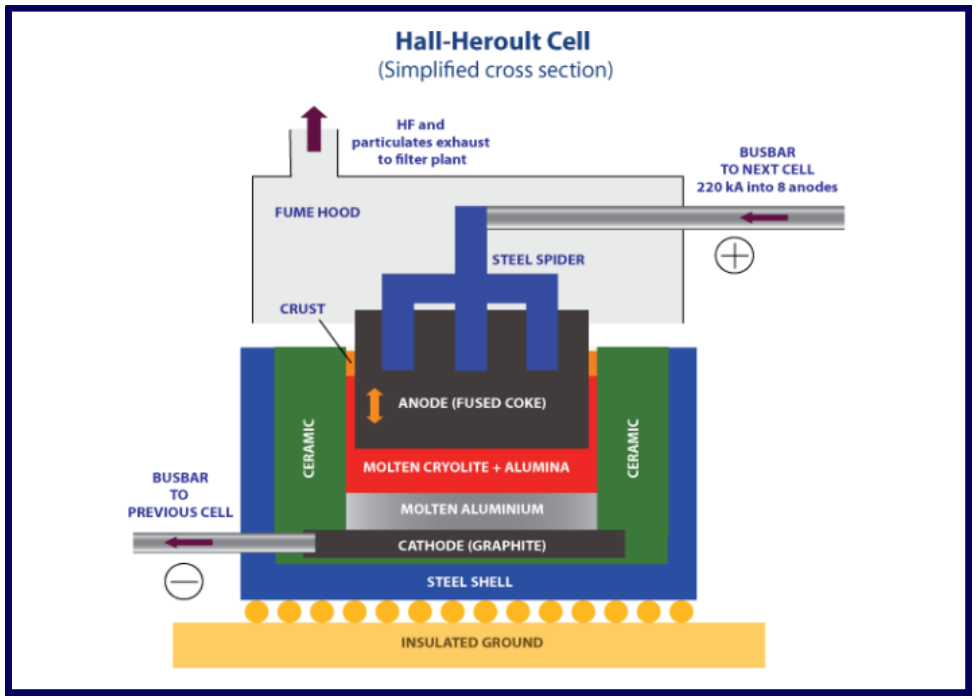

Hall–Héroult Process to Produce Metallic Aluminum

The Hall–Héroult process is the major industrial process for smelting aluminium. It involves dissolving aluminium oxide (alumina) (obtained most often from bauxite, aluminium’s chief ore, through the Bayer process) in molten cryolite, and electrolyzing the molten salt bath, typically in a purpose-built cell. The Hall–Héroult process applied at industrial scale happens at 940–980 °C and produces 99.5–99.8% pure aluminium. An electrolytic reduction process known as smelting dissolves the alumina in a cryolite bath inside carbon-lined cells, or pots. A powerful electric current, which is passed through the bath, separates aluminum metal from the chemical solution and the metal is siphoned off.

SIEVING SOLUTIONS

S49-AC Ultrasonic Sieving System for Aluminum Oxide Powder (Alumina Powder)

We have talked about the production of alumina by the Bayer process (during which aluminium hydroxide is produced) and metallic aluminum by the Hall–Héroult process, where sieving is a very important step in the processing of these powders. Weiliang has rich experience in alumina powder, aluminium hydroxide powder and aluminium powder sieving, and has cooperated with many key projects.

Aluminium oxide is processed in large quantities for different applications in a variety of industries. Sieving alumina powder is a challenge because of its lack of flow and the irregular shape of the particles. Fine sieving of alumina powder on conventional sieving machines is a very difficult process as the lack of energy inside of these machines results in very low sieving efficiency and low capacity.

Screening systems must meet stringent requirements in terms of throughput rate, screen life and separation accuracy. The production capacity and sieving quality will be greatly enhanced by using the WEILIANG ultrasonic system, which is integrated into the S49 vibrating screen.

The excitation of the screen fabric by the high frequency vibrations in the ultrasonic range reduces friction and significantly increases the screening throughput, in some cases by several times. It also significantly reduces screen wear, especially for abrasive alumina, which means a much longer screen life.

S49 Vibrating Screen Sieving Solutions for Aluminium Powder

Aluminum powder is graded into different sized particles. The size of each particle has be equal in order to obtain uniformity, which results in a high quality product for the application.

Manufacturers face many problems when using conventional vibratory sifters for sieving. A common problem is the throughput capacity of the sifter.

The Weiliang S49 vibrating screen is used to classify aluminum powder from coarse to fine powder. Each graded material is accurate, uniform and free from any foreign impurities introduced during the processing stage. These powders are then packaged and sent to different manufacturers.

YBS Tumbler Screen for Aluminium Hydroxide Powder

In the pursuit of greater throughput, Weiliang made the audacious decision to use YBS tumbler screens rather than S49 vibrating screens in the screening of aluminium hydroxide powders, and it proved to be the perfect choice at the customer’s site.

YBS Tumbler Screen with rotary brush cleaning plays very well in sieving aluminium hydroxide powder. It simulates a form of simple hand sieving motion, which are used for classification of bulk dry materials for products. The adjustment of the machine in response to the product to be screened provides an exactly defined three dimensional eccentric motion pattern with radial and tangential inclination for higher screening accuracy and greater throughput.

Why Choose WEILIANG

- S49 Vibrating Screen with intelligent adjustment device, easy for adjustment of the lead angles and exciting forces to meet individual requirement.

- S49 Vibrating Screen with quick-release clamp ring for fast replacement of screen.

- WEILIANG ultrasound system provents mesh blinding and significantly increase productivity.

- YBS Tumbler Screen with three-dimensional tumbling motion can achieve 95% or higher efficiency and accuracy.

- YBS consumes less electric power requires minimal maintenance.

- Efficiently sieve the material, producing optimum sieving outcomes.

- Higher capacity to save your time and energy on it.

- Simple assembly and disassembly to minimize maintenance cost and time.

- Fully enclosed, no material leakage.

Weiliang brings you the opportunity to build a powerful screening system in your industry that can provide a lifetime of support and performance. We also assist our customers with free material testing services and machine trials. Contact us now for customized screening solutions.