A spice is a seed, fruit, root, bark, or other plant substance primarily used for flavoring or coloring food, which are sometimes used in medicine, religious rituals, cosmetics or perfume production. In general use, herbs are a widely distributed and widespread group of plants, excluding vegetables and other plants consumed for macronutrients, with savory or aromatic properties that are used for flavoring and garnishing food, for medicinal purposes, or for fragrances —from Wikipedia

Sample test

The general sieving mesh of spices is 0.5–3.35mm. While there are some extra fine sieving requirements, such as fine black pepper with 0.25mm, which is best for soups and sauces. Customers usually have the need to remove impurities and classify into different size, so the tumbler screen is most suitable with high screening efficiency (90%-95%), large output and up to five layers. The cleaning method of spice is generally silicone bouncing balls. We can customize models and parameters according to different spice characteristics.

And for dry herbs, centrifugal sifter has the functions of crushing and sieving. Sometime it could be used as the primary screening.

Sieving Project for herbs

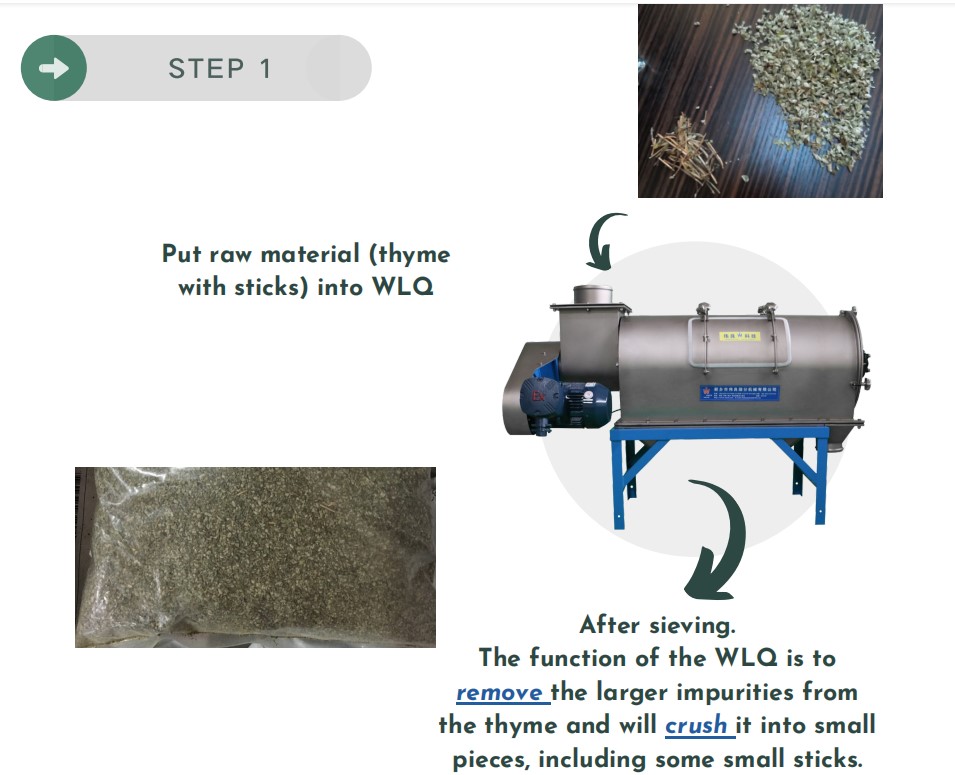

A client from Jordan named Zaki came to us to consult a centrifugal screen, hoping to help him remove impurities (samll sticks) from thyme.

Centrifugal sieve is not only able to remove coarse materials & impurities, but also able to crush herbal leaves. That made the customer feel overjoyed, because smaller particles of thyme would be better. After testing on our WLQ centrifugal sifter, three centrifugal sifters with 2mm mesh were sold undoubtly.

Please see the video link for our testing on WLQ centrifugal sifter.

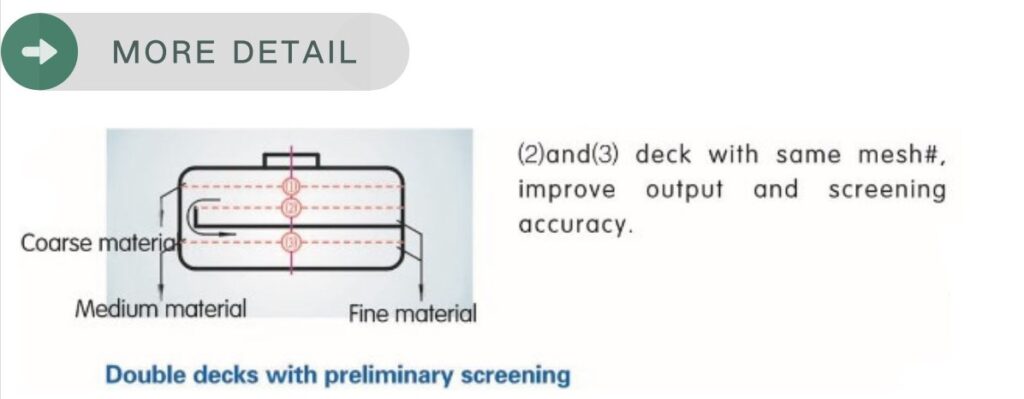

After few months, customers told us they wanted different sizes with higher precision to meet the requirements of different production lines. Therefore, we recommend a tumbler screen as the second step. We designed a double decks with preliminary screening, which improves the screening accuracy as high as 95%. Ultimately, YBS-1200 tumber screen received a positive feedback.

Importantly, although WLQ cannot remove and break 100% of the sticks in the thyme, it can basically meet the requirements of most customers. If there is no need for crushing, you can directly choose the tumbler screen with higher screening accuracy and greater output. The above two steps can be flexibly adjusted, it all depend on the customer needs for the final screening material.

Please check this video link of YBS tumbler screen.

Sieving Project for Spices

Wang Shouyi Shi San Xiang Multi-flavoured Spice Group Co., Ltd. was founded in 1984, with a total area of 230,000 m², a registered capital of 400 million RMB and nearly 2,000 employees. It is a large-scale spice condiment production enterprise with annual sales of nearly 3 billion RMB.

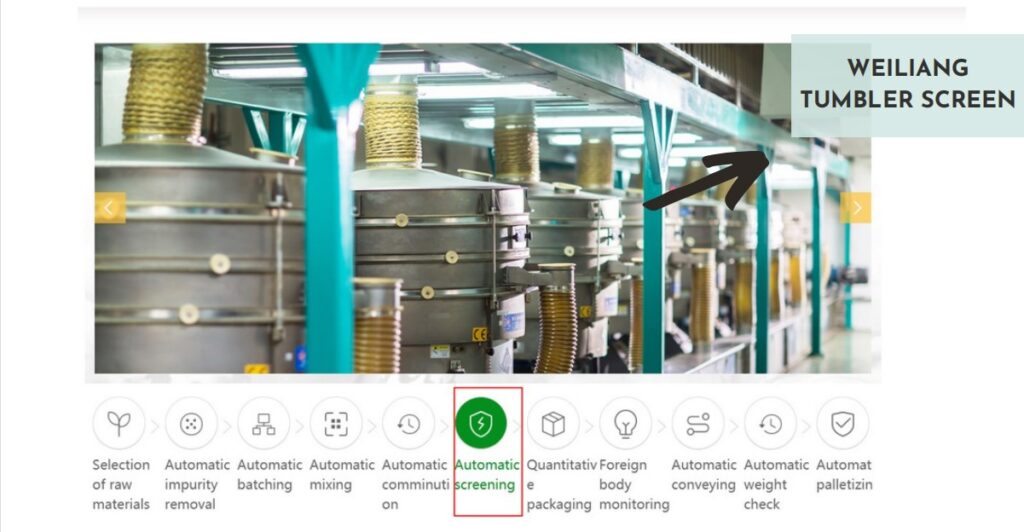

Weiliang Tumbler Screen On-site

It can be seen from the pictures on the customer’s official website,the crushed and mixed spices are put into the tumbler screen for screening in the fully automatic production line to achieve the purpose of removing impurities and fine screening.

In order to meet the needs of customers for fine screening of high precision, we have designed model of double decks with preliminary screening, the (2)and (3) deck with same mesh to improve output and screening accuracy. what’s more, the outlet is customized size and designed to be inclined to increase discharge speed. Also adds three inspection holes on top of the machine, which convenient to observe the internal screening situation in time.

In addition, the eccentricity and motor speed have been specially adjusted according to the characteristics of the spice material, which has won the consistent favourable comment of customer. The capacity of the YBS-1200 model reaches 700-800 kg per-hour.

Tumbler Screening Machine

Weiliang is the first manufacturer of tumbler screening machine in China, with years of experience and improvements, and Weiliang has sold over 3600 units of YBS units since now.

YBS Tumbler screen

Introduction

Tumbler screen simulates a form of simple hand screening. The core of the tumbler screen is the patented three-dimensional adjustment system, and the unique parameter setting is suitable for screening various products.

The material is continuously fed from the top center inlet, thereby spreading outward to across the entire screening surface. The finer particles fall through the screen, and the coarse particles successively slide towards the periphery. The material moves from the center of the screen to the edge in a spiral pattern with acceleration gradually increasing, which result even those particles that are nearly the same size as the screen mesh are screened. All the separated fractions are discharged through the lateral outlets. The sieving process is repeated on each layer.

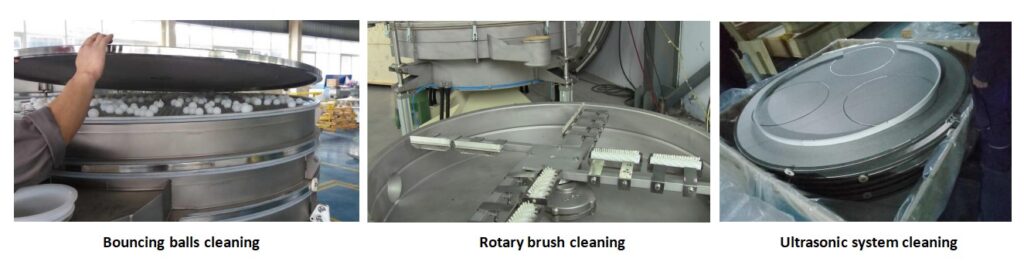

In addition, effective screen-cleaning systems are necessary to ensure the continuous operation of the machine. Three mesh cleaning methods to choose, rotary brush cleaning system, bouncing ball cleaning system and ultrasonic cleaning system.

Characteristics

- High screening efficiency, screen settings can be adjusted according to different material and capacity.

- Up to five layers and largest model to diameter 2900mm, large capacity could be reached.

- Delivered operationally ready and adjusted to each product.

- Low acceleration, long service life of all parts, low noise.

- Easy operation, screen replacement would be much more easier with pneumatic lifting device, for maximum time saving when changing screens.

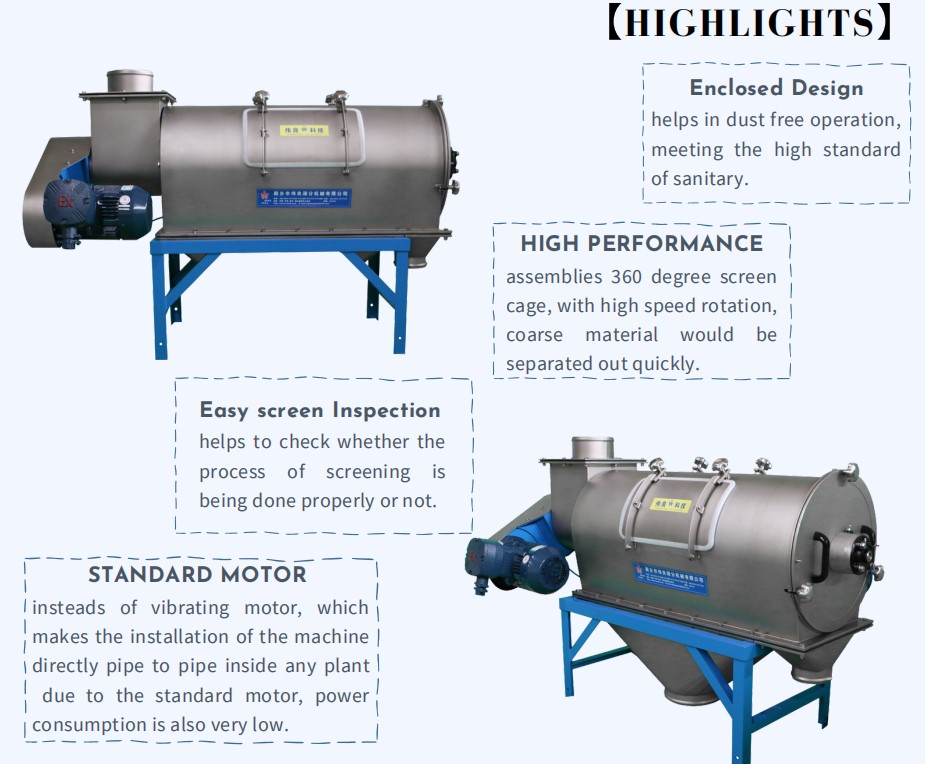

Centrifugal Screen

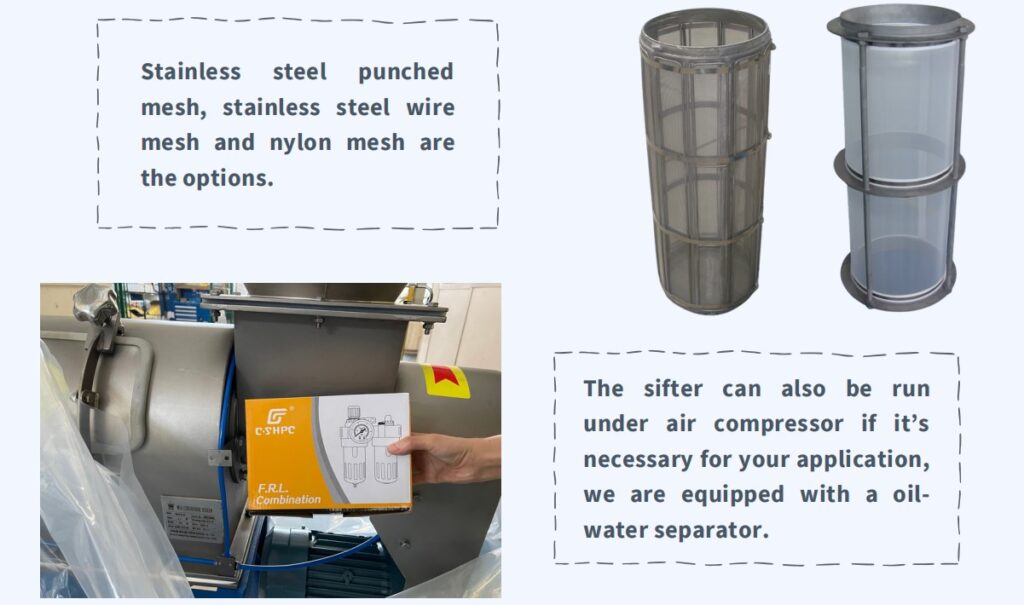

Weiliang Centrifugal screens WLQ are ideal for handling the wide variety of powder, granules and other free-flowing materials. Our high throughput centrifugal sifter is the best suited for applications where the high standard of hygiene is demanded. It also provides ease of operation and can be used on a variety of applications including classifying & De-dusting. Its unique design and structure allow more material to be sieved with fewer fines in the oversize particles, which will increase capacity also efficiency, and optimize the profits of any processing applications ultimately.

Dust free operations, Hygienic & highly efficient machine design, Screen can be checked in 360° by loosening of a knob, easy for inspection, No leakage or contamination at the oversize end, and Continuous discharge of oversize particles.

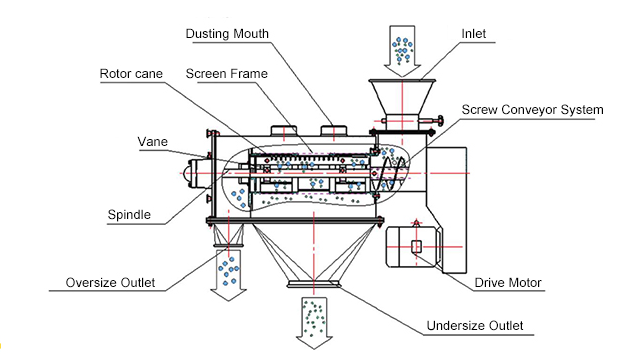

Weiliang centrifugal sifter is quite effective in processing bulk solids and powder. The cylinder screen-mesh is placed inside the machine, the materials mixed with airflow and atomization pass the screw conveyor device, enter the cylinder screen cage. Through the wheel blades in the screen cylinder, the material is subjected to centrifugal force and cyclone propulsion force simultaneously, so that the material is sprayed over the mesh, fine material discharge from fine outlet, the coarse material which cannot cross the screen cage discharged from the coarse outlet.

For more information about us, please visit our website. We’d love to hear from you!