GLOBAL PET FOOD MARKET

The pet food market consists of sales of dry dog food, dog treats, wet dog food, wet cat food, dry cat food, cat treats, and other types of pet food.

North America was the largest region in the pet food market by 2022. Western Europe was the second largest region in the pet food market. The regions covered in the pet food market report include Asia Pacific, Western Europe, Eastern Europe, North America, South America, and the Middle East and Africa.

The global pet food market grows from US$66.45 billion in 2022 to US$72.02 billion by 2023, at a compound annual growth rate (CAGR) of 8.4%. The pet food market is expected to grow to S$94.97 billion by 2027, at a CAGR of 7.2%. (Refer to PET FOOD GLOBAL MARKET REPORT 2023, Published Jan. 2023)

TYPES OF PET FOOD

| 1. Dry food: Also known as kibble, this type of pet food is convenient and can be left out for your pet to graze on throughout the day. It typically has a long shelf life and comes in a variety of flavors. |

| 2. Wet food: Sometimes referred to as canned food, wet food has a higher moisture content than dry food. It can be more palatable for some pets and may be beneficial for those with dental issues. However, it also has a shorter shelf life once opened and can be more expensive than dry food. |

| 3. Semi-moist food: This type of pet food is soft and chewy, with a moisture content in between that of dry and wet food. It is often more expensive than dry food and may contain more artificial ingredients. |

| 4. Raw food: A raw food diet for pets typically consists of raw meat, bones, and organs, with or without added supplements and vegetables. Proponents of this diet believe it better mimics a wild diet and can lead to benefits such as shinier coats, improved digestion, and better dental health. However, it requires careful preparation and can be more expensive and time-consuming than other types of food. |

| 5. Prescription diets: Some pets may have specific dietary needs due to health conditions, such as kidney disease or allergies. In these cases, a veterinarian may recommend a prescription diet that is specially formulated to meet those needs. These diets may require a prescription and may not be available in all stores. |

DRY PET FOOD MANUFACTURING

- Ingredient Selection and Sourcing

- Ingredient Weighing and Preparation

- Manufacturing of dry animal feed

- Storage and Distribution

Manufacturing of dry animal feed

Crushing–Mixing–Extruding–Drying–Coating —Cooling&Sieving—Packing

- The dry mix is combined with wet ingredients, water and steam in a preconditioner, which hydrates the powders, creates a dough and starts the cooking process. The dough then enters a machine known as an extruder, which cooks the dough under pressure. The dough exits the extruder under pressure through a die plate creating ribbons of pre-specified shapes that are then sliced into the pre-specified size using a rotary cutter.

- After extrusion and cutting are air dried in an oven to remove moisture and then cooled. Reducing the moisture content is an important step in maintaining freshness and preventing food spoilage.

- For baking, the dough is rolled out and cut into shapes and then baked in the oven.

- After drying and cooling, pet foods usually go into a rotating drum where they are evenly coated with a mixture of flavors to enhance the taste, and preservatives to prevent spoilage during the food’s shelf life. Flavors or other coatings may also be sprayed on the baked goods as they leave the oven.

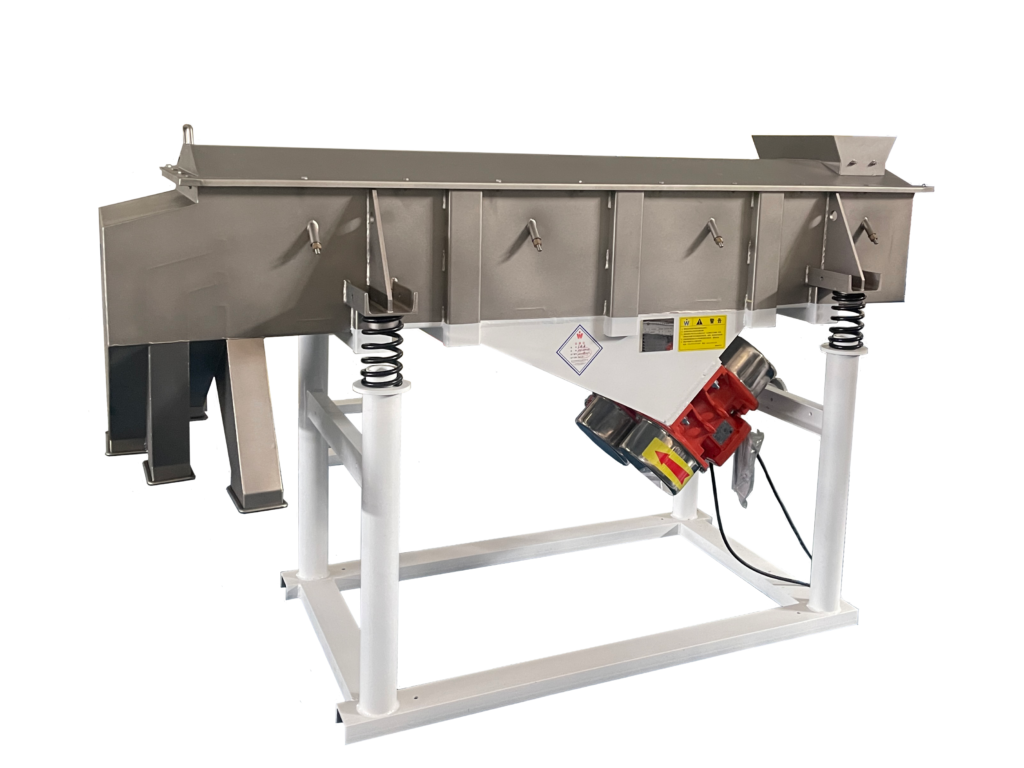

Vibrating screens will be used in the sieving process to remove impurity and to separate qualified items from unqualified ones. Packs are filled according to the declared weight of the product and the packaging is appropriately sealed to prevent contamination.

WEILIANG OFFERS DIFFERENT TYPES OF SCREENING EQUIPMENT TO MEET DIFFERENT SIEVING NEEDS OF PET FEED

WET PET FOOD MANUFACTURING

In wet pet food manufacturing, the product is actually normally cooked in the can (or another container). The ingredients are carefully measured and added to the container – this includes animal products such as meat and often grains, thickeners, vegetables and additional vitamins and minerals. The container is then sealed and the product cooked, finally labeled and stored.

CUSTOMER CASE SHARE

- Material: Fish food

- Machine type: S49 vibrating screen

- Capacity: 800kg/h

- Purpose: Impurity removal and classification

- Challenges: Sticky, easy to block mesh

- Material: Dog/Cat food

- Machine type: SZF Linear Vibrating Screen

- Purpose: Impurity removal and classification

- Challenges: Highly oily, sticky, easy to block mesh

The dry pet food manufacturing industry has made significant progress in recent years. Here are some of the changes and advancements:

1. Improved safety standards: In response to the various pet food recalls over the years, the industry has improved safety standards and implemented more rigorous quality control protocols.

2. Customization: With the rise of e-commerce and direct-to-consumer brands, manufacturers are now offering customized diets based on the unique needs, preferences, and health conditions of individual pets.

3. Sustainability: Many manufacturers are prioritizing sustainability by using eco-friendly packaging materials and sourcing ingredients from environmentally responsible suppliers.

4. Higher quality ingredients: Manufacturers are using higher quality ingredients such as whole meats, whole grains, and fruits and vegetables to create nutritionally balanced and tasty meals for pets.

5. Technological advancements: Advances in technology have allowed for better control over the manufacturing process, accurately monitoring and controlling the temperature and humidity of the drying and baking process.

Overall, the dry pet food industry continues to evolve in terms of quality, safety, and sustainability, providing pets with better nutrition and healthier choices.