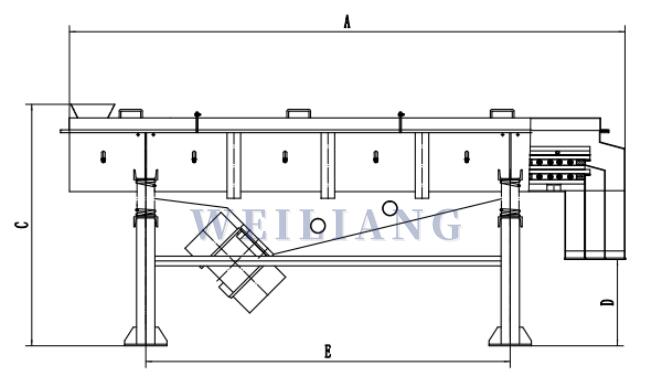

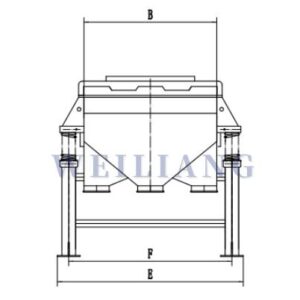

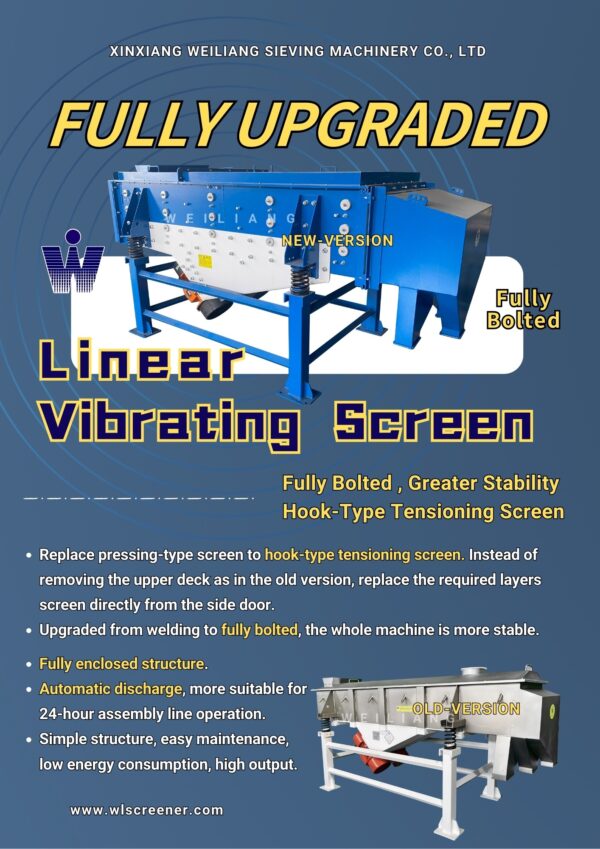

A linear vibrating screen is a screening equipment that utilizes linear motion to separate and classify various materials. It works by feeding the material evenly onto the screen surface and moving in a straight line. The motion of the screen is generated by vibration motor and is transmitted to the screen surface through the vibration mechanism. The main components of a linear vibrating screen include the screen frame, screen mesh, vibration motor and spring. The screen frame holds the screen mesh and provides support for the screening surface. The screen mesh is the actual screening surface that allows the passage of undersized particles while retaining oversized particles.