WHAT IS SAP

A super absorbent polymer (SAP) (also known as slush powder) is a water-absorbing hydrophilic homopolymer or copolymer that can absorb hundreds to thousands of times its own weight in water. This polymer securely retains the absorbed liquids even when subjected to pressure. It majority are made of sodium polyacrylate or potassium polyacrylate and are available in granular or fiber form.

THE TYPES OF SAP

Improved SAP – Improved on some sides like:

- Starch-based SAP – The biodegradable type SAP;

- Minerals-based SAP (for plants) – Available in soil for years;

- SAP with improved catalyst – High expansion ability (for water blocking of cable);

- Cation type SAP – concrete additive.

Common SAP

- Potassium polyacrylate – mainly used in agriculture as a water-retaining agent;

- Sodium polyacrylate – widely used in industrial production such as Paper diapers, Sanitary napkins, Ice bags, Air fresher, Expanding rubber, etc.

SAP APPLICATION

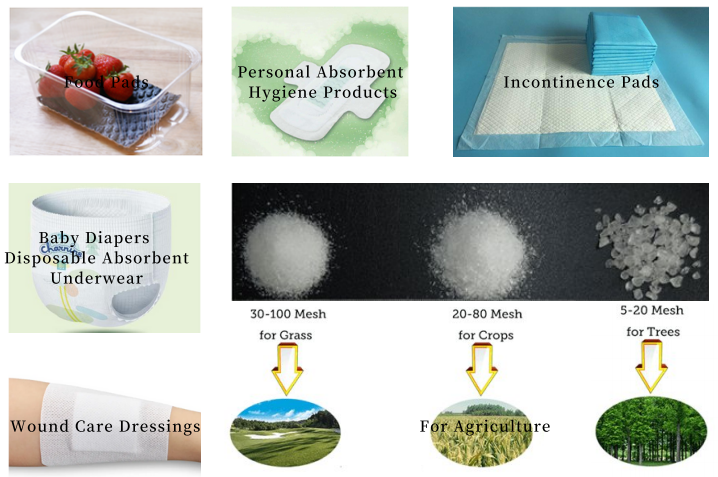

(Image Reference-- SOCO Blog: Super Absorbent Polymers 2022)SAP have a wide range of applications, including hygiene materials used primarily in disposable diapers and sanitary products, as well as non–hygienic applications such as agriculture and horticulture, pet, construction and civil engineering and so on.

SAPs are designed to hold fluids like baby diapers/nappies, incontinence products, and feminine hygiene pads and liners. SAP are also used in industrial applications such as agriculture to regulate water release in arid soils and adsorb excess water in damp climates.

Other applications include electrical cable protection coatings, food packaging, and medical/medical waste adsorbents.

SAP MARKET TRENDS

The SAP market provides a positive outlook for the market for a variety of reasons.

Firstly, increasing demand for premium quality diapers as a result of rising parental concerns about their babies’ health and hygiene. Furthermore, the market is being driven by women’s increasing awareness of personal hygiene and, as a result, rising sales of sanitary napkins. Aside from that, the increased number of farming activities is fueling demand for SAPs in the agriculture sector to reduce soil erosion caused by surface run-offs, fertilizer and pesticide leaching into groundwater. SAPs are also used in the safe management of infected respiratory secretions due to their disinfectant properties. This, combined with the rising prevalence of viral infections, is fueling market growth.

| The global super absorbent polymer market was worth USD 8.25 billion in 2021 and is expected to reach USD 14.26 billion by 2030, growing at a CAGR of 6.27% between 2022 and 2030. |

| Asia-Pacific is the most promising market for SAP materials, accounting for more than 40% of global demand, and will likely dominate the market in the foreseeable future. |

| According to the World Bank Group, the global population aged 0 to 14 will reach 2,08 billion by 2050. The personal hygiene application dominates the market for SAP. |

MANUFACTURING PROCESS OF SAP

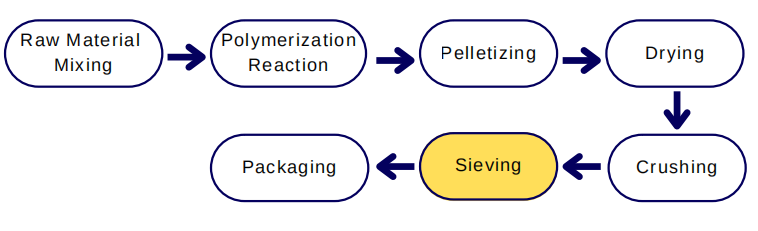

In brief, the whole process of producing SAP contains seven steps: mixing of raw materials, polymerization reaction, pelletizing, drying, crushing, sieving, and packaging of finished products.

More specifically, there are three methods used to produce the superabsorbent polymers.

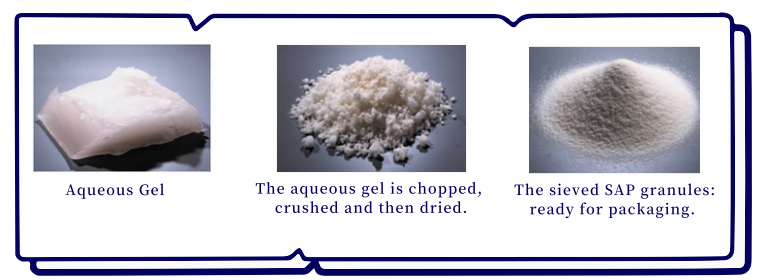

1.GEL POLYMERIZATION

(Image reference Edana: What is SAP – superabsorbent polymers)| Gel polymerization is acrylic acid, sodium hydroxide, water, cross linking agents, and UV initiators are all sprayed onto a moving belt inside a long chamber with a row of high intensity UV lights. The UV radiation causes the components to react and crosslink, resulting in the formation of sodium polyacrylate. The mixture swells in the chamber to form a ‘wet cake,’ which is then conveyed to drying equipment after being ground up in a mill. |

2. SUSPENSION POLYMERIZATION

| Suspension polymerization is typically sodium hydroxide, acrylic acid, initiators, crosslinking agents and a surfactant are suspended in a tank reactor in an organic solvent. Because acrylic monomer is insoluble in solvent, it reacts with the base to form cross-linked sodium polyacrylate polymer beads. Close control of the temperature, residence time, speed, and type of agitator in the reactor, as well as the concentration of the multiple additives, determines the size of the polymeric beads. The emulsion is drawn from the reactor continuously, and the spheres are filtered out of solution, agglomerated, and dried. The organic solvent is recycled and reused in the reactor. |

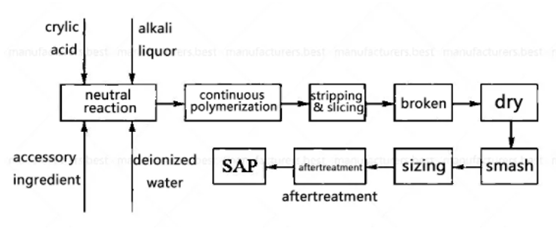

3. Solution Polymerization

(Image reference--Manufacturers.Best: Super Absorbent Polymer Manufacturing Process, 2022)| Solution polymerization is the acrylic acid monomer is mixed with an initiator, sodium hydroxide, and crosslinking agents in a non-reactive solvent. The reaction produces a polymer that is also solvent soluble. The desired degree of conversion can be achieved without bulk polymerization as in suspension polymerization by carefully controlling the temperature and concentration of ingredients. After the excess solvent is removed, the “liquid superabsorbent polymers” are ready for use. |

(Reference -- Gelok International Corporation: What is Super Absorbent Polymer & Answers to All of Your Questions)

WEILIANG YBS TUMBLER SCREEN IN SAP APPLICATION

According to report of Gelok International Corporation, Major manufactures of SAP with estimated world with wide capacity are as following:

- Sumitomo Seika Chemicals (Japan) – 450,000 tons

- Nippon Shokubai (Japan) – 700,000 tons

- Sanyo Chemical / SDP Global (Japan) – 420,000 tons–WEILIANG has been working with;

- BASF (Germany) – 600,000 tons

- Evonik (Germany) – 500,000 tons

- LG Chem (S. Korea) – 400,000 tons

- Taiwan Plastics (China) – 200,000 tons–WEILIANG has been working with;

- Yixing Danson (China) – 420,000 tons

- Satellite Science & Technology (China) – 200,000 tons

- Shenghong Holding Group (China) – 80,000 tons

- Quan Zhou Technology (China) – 140,000 tons

- HIGH PRECISION

- HIGH CAPACITY

- ERT ANGLE ADJUSTABLE

- LONG SERVICE LIFE

- EASY OPERATION

- FEW MAINTENANCE

HOW TO SCREEN SAP EFFECTIVELY

- Sieving material: SAP

- Model: YBS-1600 / YBS-2000-2S / YBS-2000-4S

- Sieving Challenges: Electrostatic, Agglomerative, Viscous

The traditional method of sieving SAP is with a vibrating screen, but there is a consistent problem of low capacity. Weiliang Tumbler Screen will solve these screening issues and provide a unique screening effect.

Weiliang has cooperated with Sanyo Chemical (Japan), Taiwan Plastics (China) , Wanhua (China), Boya (China), Hanhua Chemical (China) etc…

YBS Tumbler Screen for sieving SAP, received good feedback from our customers. Welcome to contact us, we are happy to hear from you!