WHAT IS PETROLEUM COKE

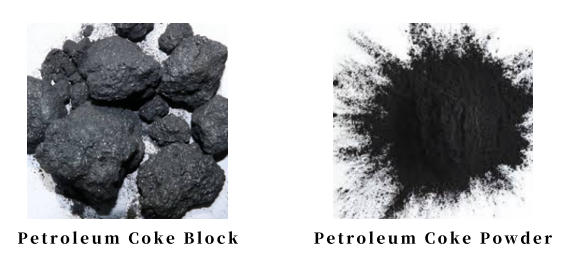

Petroleum coke is a hard solid petroleum product in black or dark gray, and is characterized by metallic luster and porosity. It is carbon-shaped stuff composed of tiny graphite crystals formed into granules, columns or needles. It is the carbonized product of heavy residue produced by crude oil processing (atmospheric and vacuum distillation, catalytic cracking, etc).

Petcoke can take two different forms: green petcoke which is used as a fuel, and calcined petcoke which is used as a feedstock by manufacturer for a wide range of products such as aluminum, paints…

Petroleum coke is a valuable and essential commercial product that is used directly in a wide range of applications including aluminum manufacturing, fuels, and numerous other products including steel, glass, paint, and fertilizers.

TYPES AND USAGES OF PETROLEUM COKE

- 1. Needle coke

This grade of coke has a crystalline structure, making it a favorable material in the production of components such as electrodes. It’s manufactured from a low-sulfur FCC slurry processed in a specific type of coker. It is mainly used as high-power and ultra-high-power

graphite electrodes in steelmaking after calcination, and some of it is used as cathode materials.

- 2. Honeycomb coke

Honeycomb coke is considered an intermediate type. It consists of uniformly distributed ellipsoidal pores. It’s characterized by low electrical conductivity and low coefficient of thermal expansion.

- 3. Shot coke

This type is undesirable as it has an irregular structure that makes it very difficult to handle. As such, it’s unacceptable for most applications. When manufacturing petroleum coke, refiners control the feed of vacuum resid to avoid producing shot coke. And can only be used as industrial fuels such as power generation and cement.

- 4. Sponge coke

Physically sponge coke can be described as porous. The individual spheres are not apparent and the coke itself has a continuous structure. While the electrical conductivity of this type of coke is low, its structure makes it appropriate for the production of anodes. It is mainly used in aluminum industry and carbon industry.

PETROLEUM COKE PRODUCTION METHODS

Coking is a refinery unit operation that upgrades material called bottoms from the atmospheric or vacuum distillation column into higher-value products, producing petroleum coke.

Petroleum coke is produced primarily through delayed coking and fluidized coking. Essentially, it involves thermal decomposition of heavy residuals from atmospheric and vacuum crude oil processing units into gas, light and middle distillates, and coke.

Both are physical processes that occur at slightly higher than atmospheric pressures and temperatures greater than 900oF, thermally cracking the feedstock into products such as naphtha and distillate while leaving petroleum coke behind. Petroleum coke is

either sold as fuel-grade petroleum coke or undergoes an additional heating or calcining process to produce anode-grade petroleum coke, depending on the coking operation temperatures and length of coking times.

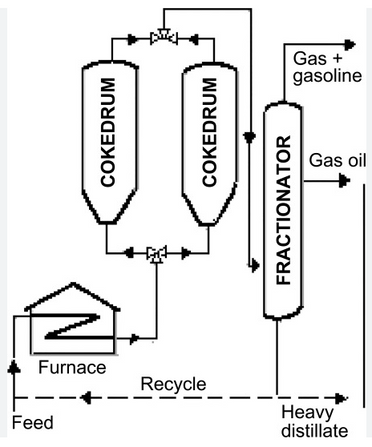

Image reference to James G. Speight in Heavy and Extra-heavy Oil Upgrading Technologies 2013, from Science Direct

DELAYED COKING

With delayed coking, two or more large reactors, called coke drums, are used to hold, or delay, the heated feedstock while the cracking takes place. Coke is deposited in the coke drum as a solid. This solid coke builds up in the coke drum and is removed by hydraulically cutting the coke using water. In order to facilitate the removal of the coke, the hot feed is diverted from one coke drum to another, alternating the drums between coke removal and the cracking part of the process.

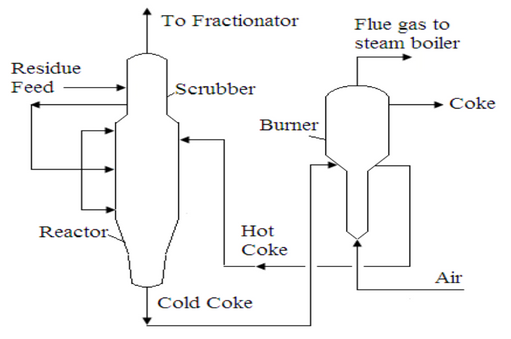

FLUID COKING

With fluid coking, the feed is charged to a heated reactor, the cracking takes place, and the formed coke is transferred to a heater as a fluidized solid where some of it is burned to provide the heat necessary for the cracking process. The remaining coke is collected to be sold.

PETROLEUM COKE POWDER PRODUCTION PROCESS

- Crushing – Petroleum coke blocks are crushed by the crushing equipment.

- Drying – Some sites which have high requirements on the moisture content of petroleum coke will add the drying process.

- Sieving – The crushed and dried petroleum coke is sieved to obtain different size.

- Grinding – After crushing, drying and sieving, the petroleum coke is processed in a deeper level and ground to obtain finer powder for different purposes. For example, green coke is used in glass and ceramic factories, and generally needs to be processed to 180 mesh. In addition, low sulfur, high quality calcined petcoke used for making graphite electrodes needs to be processed to 200 mesh.

- Conveying – Conveying equipment is used throughout the whole process.

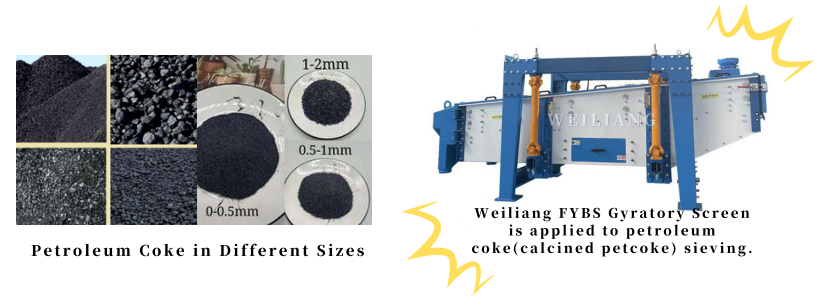

PETROLEUM COKE (CALCINED PETCOKE) SCREENING

- Sieving Purpose:

Classification: separate into different sizes.

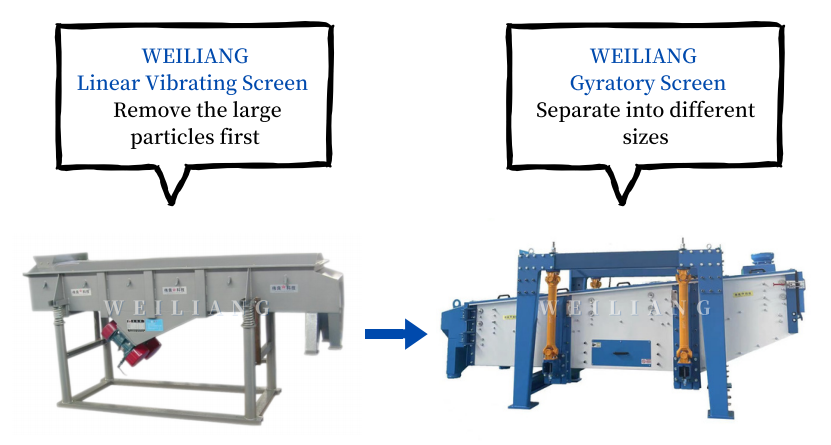

- Screening Model:

After crushing, the petroleum coke (calcined petcoke) enters the Gyratory Screen for grading. The capacity of FYBS-1536-5S with 1-40mm screen can reach 5-8 t/h. In addition, some customers site use Weiliang linear vibrating screen to remove the large particles first. Material larger than the screen aperture will return to the crusher, and the undersize enters the gyratory screen for further classification. After screening, it enters to the packing stage.

- Screening Challenges and How We Do

Easy to block the screen—— due to the shape of the crushed petroleum coke, the screen mesh holes would get blocked easily.

Weiliang solves screen blocking problems very well due to the unique design of gyratory screen and the combination of perforated palte & bouncing balls cleaning system.

Any questions or concerns about our gyartory screen in sieving petroleum coke application, please feel free to contact us!