WHAT IS SALT

Salt is a mineral composed primarily of sodium chloride (NaCl), a chemical compound in the salt class; salt in the form of a natural crystalline mineral is known as rock salt. Salt mainly consists of sodium chloride (NaCl). Trace elements may be present in sea salt and mined salt. Mined salt is frequently refined. Salt crystals are translucent and cubic in shape; they are normally white but may have a blue or purple tinge due to impurities.

Types:

Salts are classified in a variety of ways. Alkali salts are salts that produce hydroxide ions when dissolved in water, whereas acid salts produce hydrogen ions when dissolved in water. Neutral salts are salts that are neither acidic nor basic in nature.

Salt can also be classified as edible salt, industrial salt, and absolute salt. The processed salt with sodium chloride as the main component obtained from seawater, underground rock (mineral) salt deposits, and natural brine is the edible salt used in people’s daily lives. Table salt is a refined salt that contains 97- 99 percent sodium chloride. To make it free-flowing, anticaking agents such as sodium aluminosilicate or magnesium carbonate are usually added. Iodized salt (potassium iodide) is widely available.

Industrial salt has a broad meaning in industrial production; it can refer to pure sodium nitrite or sodium chloride containing sodium nitrite. Industrial salt contains a large number of carcinogens nitrite, but it may also contain lead, arsenic, and other harmful substances.

USAGE OF SALT

Salt is added to promote color development in bacon, ham and other processed meat products. As a preservative, salt inhibits bacterial growth. In sausages, salt actsas a binder, forming a binding gel of meat, fat, and moisture. Salt is used in many dairy industries to control the color, fermentation, and texture of cheese. Salt is used in canning as a flavor enhancer and preservative. In baking, salt is added to control the rate of fermentation in bread dough.

| 1. Food Industry Salt is essential for life in general, and saltiness is one of the basic human tastes. Salt is added to food as a flavor enhancer, preservative, binder, fermentation-control additive, texture-control agent, and color developer. |

| 2. Medicine One of the primary solutions for intravenous therapy is sodium chloride mixed with water. Nasal spray often contains a saline solution. |

| 3. Cleanser salt is also used as a cleansing agent in many brands of shampoo and toothpaste. |

| 4. Firefighting Sodium chloride is the principal extinguishing agent in fire extinguishers (Met-L-X, Super D) used on combustible metal fires such as magnesium, potassium, sodium, and NaK alloys (Class D). |

| 5. Water Softening Hard water contains calcium and magnesium ions and leads to the buildup of a scale or film of alkaline mineral deposits in household and industrial equipment and pipes. Commercial and residential water-softening units use ion-exchange resins to remove ions that cause the hardness, which generated and regenerated using sodium chloride. |

| 6. Industrial Uses ~Salt is for de-icing and anti-icing of roads. ~Salt is used to secure the soil and strengthen the foundations on which highways are built. ~Salt is used in oil and gas exploration to flocculate and increase the density of the drilling fluid in ~order to overcome high downwell gas pressure. ~Salt is used in textiles and dyeing as a brine rinse. ~Salt is used to bleach wood pulp in the pulp and paper industry. ~Salt is used in the production of buna, neoprene, and white rubber in rubber production. |

HOW SALT IS PRODUCED

1.Solar Evaporation Method

Sea salt is made on a much smaller scale, using ancient, skilled techniques. Sea salt production can only take place in areas with low rainfall to allow for enough time for evaporation.

Salt accounts for about 3.5 percent of the world’s oceans. When producing sea salt on an industrial scale, seawater is placed in large “concentrating ponds” to allow efficient evaporation from the sun and the wind. Solar salt production is, typically, the capturing of salt water in shallow ponds where the sun evaporates most of the water. The concentrated brine precipitates the salt which is then gathered by mechanical harvesting machines. Any impurities that may be present in the brine are drained off and discarded prior to harvesting.

2.Rock Salt Mining Method

Rock salt (also known as halite) is present in the rocky under layers of the Earth’s surface and can be extracted through deep-shaft mining. Large machines perform various operations as they travel through vast cave-like passageways.

Rock salt is extracted through dynamite, similar in fashion to the mining of any other mineral. Once it is brought to the Earth’s surface, it is crushed and used for industrial and other non–food purposes. This type of salt contains many minerals and other impurities.

The above ground processing of the rock salt consists of screening the mined salt into various marketable sizes by sorting through mechanically operated screens.

3.Vacuum Evaporation Method

Another method of salt production is the evaporation of salt brine by steam heat in large commercial evaporators, called vacuum pans. This method produces a very pure salt with a fine texture that is primarily used in applications that require the highest quality salt.

The first stage of the operation is referred to as solution mining. Several hundred to 1,000 feet apart, wells are drilled into the salt deposit. These wells are linked together using lateral drilling. Water is pumped down one well, the salt below is dissolved, and the brine produced is forced to the surface via the other well. It is then piped into large storage tanks.

Next, the brine is pumped into vacuum pans. They are normally arranged in a series of three, four or five, with each one in the line under greater vacuum than the preceding one.

Steam is fed to the first pan during the vacuum pan process. The brine in the pan begins to boil as a result. The boiling brine’s steam is then used to heat the brine in the second pan. Because the pressure in the second pan is lower, the steam produced by the boiling in the first pan can heat the brine in the second pan. Each pan after that reduces the pressure even more. This allows the steam produced by the boiling brine in the previous pan to be used to heat the brine in the next pan. While the boiling operation could be completed in a single pan, several pans in a row produce more salt per pound of steam, allowing for greater energy efficiency.

HOW TO SIEVE SALT

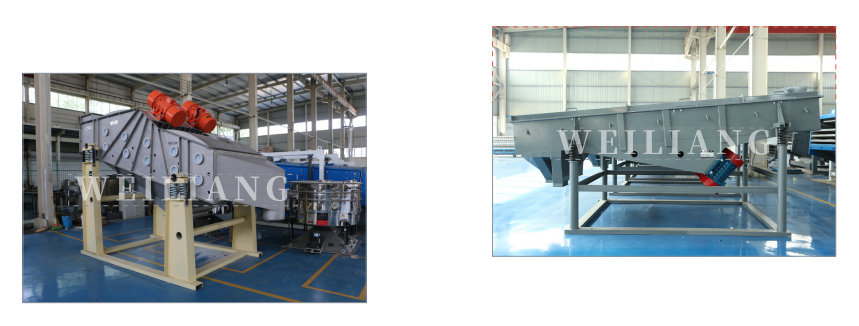

In the past years, linear vibrating screens or probability screens are widely used in screening salt.

Nowadays, customers are often forced to increase plant space and use many units to meet production requirements due to the low capacity of linear vibrating screen. What’s more, linear vibrating screens and probability screens are often used for coarse screening because of lower precision. Therefore, a machine with both high capacity and high precision is required.

WEILIANG Gyratory Screen, used for classification of bulk dry materials, both meets the requirements of high precision and large throughput. It with the highest performance per screening area provides sharper separations, higher volume, low maintenance, unparalleled material spread-ability and lower finished product wastage.

EDIBLE SALT SCREENING CASE SHARING

Screening Need: Impurity Removing (Remove large particles or ultra-fine powder)

Screening Challenges and How Weiliang Do

1. Due to the strong corrosive characteristics of salt, even if the machine is made of 316L, rust spots will inevitably appear on the machine after long-term use. Weiliang will use a special surface anti-rust treatment on the basis of 316L material to prevent rusting.

2. In addition, the low output of linear vibrating sieve or probability vibrating screen is insufficient to meet the high capacity requirement of salt screening. Furthermore, the 316L material may cause them to become brittle due to their structure, making them prone to cracking. Therefore, the gyratory screen with high output and high precision developed by WEILIANG has gradually become the machine of choice for salt screening.

Any questions you may have, please feel free to contact us!