Baobab fruit

The baobab processing machine is an innovative way to make the most of your dried, organic baobab fruit. The machine is efficient and time-saving in processing baobab pulps into fine powder. If you are looking for more information on how to produce fine baobab powder in an automatization way, be sure to check out our article post on the topic.

What is baobab and the benefits?

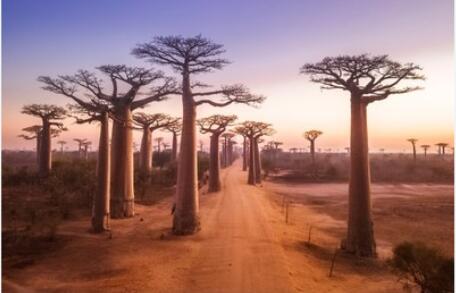

Baobab is the exceptional superfruit as “Tree of Life” in Africa. Baobab trees grow wild throughout the mainland Africa and can become massive. It is the only fruit in the world that dries naturally on the branch. Baking in the sun for 6 months, the prickly green, furry coating transforms into a smooth brown, coconut-like shell. Inside the hard pod, the pulp is naturally dehydrated. The pod contains incredibly nutrient dense powder and seeds. Baobab powder is a fine, light-brown color and has a slightly sour taste.

The benefits of baobab powder

The benefits of consuming baobab powder include: high calcium and vitamin C content, rich in prebiotic fiber and antioxidants, high omega-fatty acids content, boosting the immune system, supporting healthy skin etc. It can be used as a supplement or added to food for flavor and nutrition or medicinal purposes.

However the manual methods that are currently used by African women to separate the powder and the seeds requires a lot of time and energy. This article is about one type of centrifugal sieve machine that will process the baobab pulps in an efficient way and boost economic production in Africa.

The global baobab powder market development trends

The global baobab powder market is expected to grow at a significant CAGR in the next five years. It is estimated that by 2027 year this industry will become an eight-billion dollar marketplace according to the reports from research and markets.

Amid the COVID-19 crisis, the global market for baobab powder, estimated at US$6 Billion in the year 2020, is projected to reach a revised size of US$8.5 Billion by 2027, growing at a CAGR of 5.1% over the period 2020-2027. The U.S. Accounts for Over 27.1% of Global Market Size in 2020, While China is Forecast to Grow at a 7.8% CAGR for the Period of 2020-2027. The global market for baobab fruit products is growing prospectively.

How to make baobab powder with the baobab processing machine

After breaking the baobab pods and taking out the pulp, we will need the baobab processing machine to produce the highly nutritious baobab powder.

Here introduce the centrifugal sieve for processing fine baobab powder project, with both crushing and sieving fuction. It is quite effective in processing bulk powder, designed to separate particles of different sizes into two product streams and to remove impurities and oversize materials.

WLQ centrifugal sieve

After raw material being feeded, it will be conveyed into the screen cylinder part, under the strong centrifugal force, fine material would pass through the mesh hole and being discharged from the bottom port, and coarse material would come through the side discharge port.

| Option one | Single unit of WLQ 18-85 |

| Option two | Two units of WLQ 18-85 as 2-in-1 design |

In baobab project to process fine powder, there are two options, one option is using one unit of centrifugal sifter with two processing steps; and another option is using two units of centrifugal sifter machines (2-in-1 design) as a production line.

Single unit

With 1 set of baobab processing machine, we will need two producing steps:

1) First we need to use stainless steel mesh to remove the baobab seeds and fibers

2) Then replace to the sieve cage of nylon mesh to separate the final fine powder.

Replacement of the sieve cage of nylon mesh is very convenient, just open the side door by lossening the screws, take out the sieve cage of SUS mesh, then put the one of nylon mesh would be ok. It takes only 3-5 minutes for the replacement process, very easy to operate.

2-in-1 design

Another option for baobab processing machine would be 2-in-1 design of centrifugal sifter machinery for continuous processing.

Top machine with SUS mesh and bottom machine with nylon mesh. The baobab seeds and fibers would come out through the side discharge of the top unit, the crushed powder goes directly into the bottom unit, coarse powder and small fibers come through the side discharge and fine powder would be discharged from the bottom outlet.

The whole processing progress is continuous, seeds&fibers, coarse powder and fine powder would be discharged and collected separately. The final powder is very clean and fiber-free.

How to find a reliable manufacturer for baobab pulps processing machine

If you are looking for a supplier of baobab processing machinery for your project to process high quality powder and seeds, you are at the right place. Besides the knowledge about centrifugal sieve, the machine efficient in processing baobab pulps, other consideration you should know about the supplier like their quality, their services, their experience in baobab project etc.

Weiliang is the manufacturer of fine sieving machines, main products are centrifugal sieve, vibrating sieve, tumbler screener and gyartory sifter. Here please visit our website for more information about us. Also welcome to visit our factory online by clicking the VR link.

Our stories with baobab, the magic fruit

The first time that we knew about baobab fruit could be back to 2014 year, with one customer from Senegal, though no further progress at last since his customer decided to continue producing baobab pulps manually, but we learned a lot during negotiations with him, he told us many usual information about baobab, and showed us his small test to explain his thoughts to us, we are still grateful to him.

Test by our customer

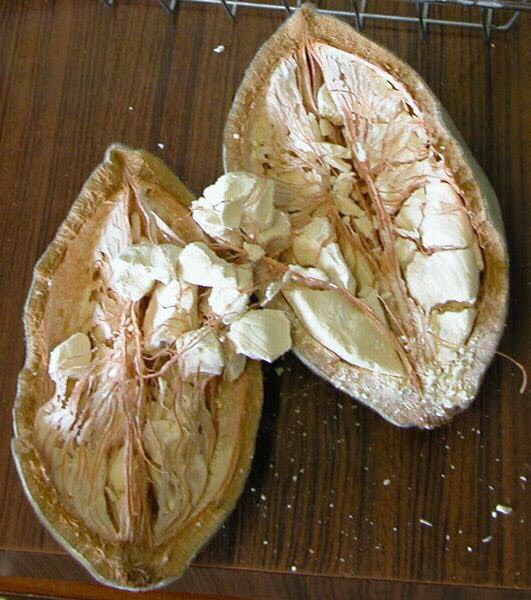

The second opportunity was in 2017 year, one Polish customer sent us some sample of baobab pulps from Angola, we were greatly appreciated for his trusts to us. It took around three months for us to clear the customs to receive the sample at that time, while we finally could made testing and independent study on the project. Heres the image of the baobab sample.

Baobab sample we received

The testing result turned out very great, please check the testing video for reference.

Since then we are able to develop more into the baobab market, and work together with more African manufacturers of baobab products. Also we have made improvements and solutions according to customers’ feedback for better operation and durability.

If you are in the business of manufacturing baobab products, or you have any questions or need more information about the machine, please feel free to contact us. We would be happy to help.

Other application about baobab products

Nearly every part of baobab is useful. Besides the powder which can be used in a wide range of consumer products such as juices, smoothies, ice creams, and herbal teas, energy and cereal bars, biscuits, and and enhance the nutritional value. The fruit has other valuable parts for more applications.

The seeds can be roasted and ground for use in a drink, pounded to extract the oil within, fermented to use as a flavoring, roasted as a snack, or used to thicken soups. The leaves are cooked fresh as a vegetable, made into a relish, or dried and crushed for later use in recipes during the dry season. The young tree sprouts can be eaten like asparagus. The wood is used for fuel and timber etc.

Baobab oil

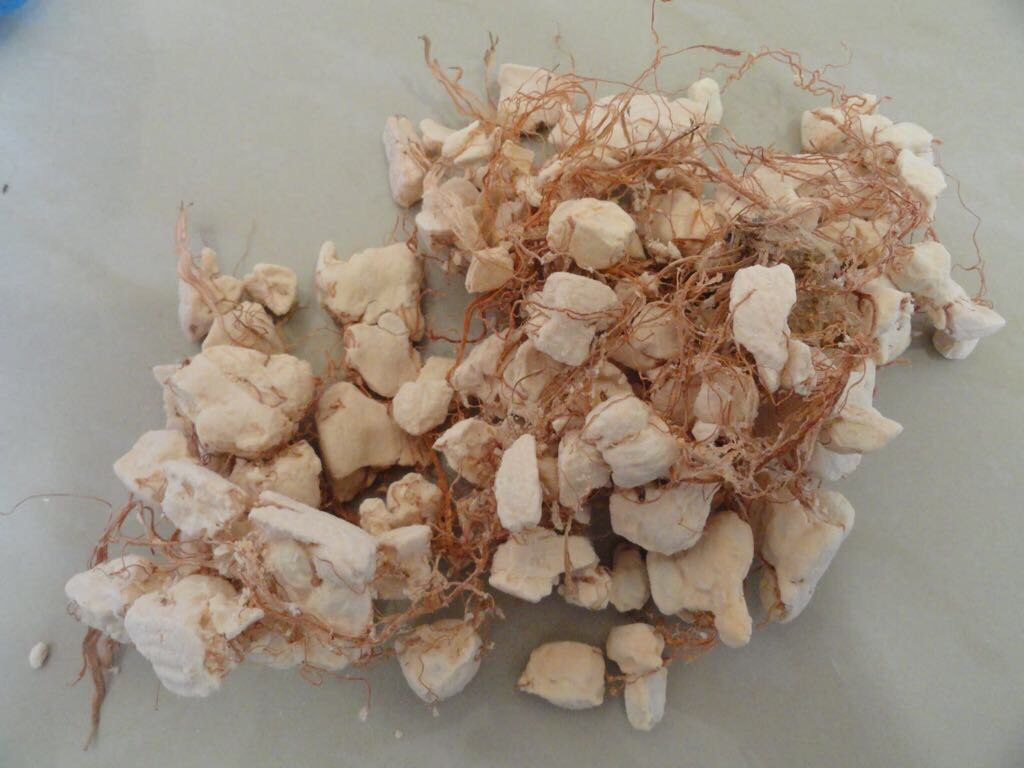

Baobab seeds

Baobab oil is cold-pressed from seeds inside the pulp by oil press machine for various uses, and it is used from cooking to hair care and skin care. It is rich in omega-3 fatty acids, Vitamin E, Calcium, Alfa and Beta Carotenes, Uronic Acid, Tannins and Phytosterols, huge market for baobab oil, many baobab fruit suppliers are also looking for the baobab oil press machine.

Baobab leaf powder

Baobab Leaf

The leaves can be dried and pounded to make baobab leaf powder, which is a source of food and is often added to stews, soups and gravy as a thickening agent.

Baobab seed endocarp powder

Baobab seed endocarp powder

Although covered with a hard shell, Baobab seed endocarp powder is rich in fatty acids and sterols and makes an excellent additive for vegan and vegetarian food supplements for hearts and cholesterol.

The baobab processing machine is the ideal equipment for separating out seeds and sieving fine powder. It can help you get a high yield and good quality of baobab powder. The machine has been proved to be reliable and efficient in many cases. Since now Weiliang has exported to Sudan, Angola, Nigeria, Guinea, Tanzania, Ghana and Denmark for baobab projects. Hope we could have more successful business in this market in the future.

No matter you are in the rigid need of the baobab processing machine, or during the stage for investment research, please feel free to contact us, we’d love to hear from you!