WHAT IS CITRIC ACID

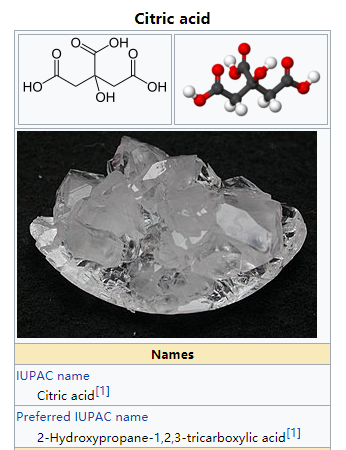

The citric acid (CA) with systematic International Union of Pure and Applied Chemistry (IUPAC) name 2-hydroxypropane-1,2,3-tricarboxylic acid is an intermediate in the CA cycle in the metabolism of all aerobic organisms.

Citric acid is a colorless weak organic acid. It can be found in many fruits and vegetables, particularly citrus fruits, but it is also manufactured. In biochemistry, it is an intermediate in the citric acid cycle, which occurs in the metabolism of all aerobic organisms.

Citric acid is a common food preservative and flavoring additive. It is generally recognized as safe (GRAS) as a direct food additive by the United States Food and Drug Administration (FDA).

Once dissolved in water, it shows weak acidity but a strong acid taste that affects sweetness and provides a fruity tartness for which it is widely used to complement fruit flavors in the F&B industry. In combination with citrate, the acid shows excellent buffering capacity, while its excellent metal ions chelating properties add to the physicochemical properties that make it ideally suited for food, cosmetic, and nutraceutical and pharmaceutical applications.

CITRIC ACID USAGE

FLAVORING AND PRESERVING FOOD

Citric acid can be added to a variety of processed and packaged foods and beverages, including ice cream, sorbets, sodas, and wine. It is used as a preservative, emulsifier, and flavoring agent. Citric acid is also used to help prevent botulism in many canned and jarred foods.

ANTIOXIDANT

Citric acid-derived antioxidants can help keep food edible for a longer period of time. Citric acid contains ascorbic acid, also known as Vitamin C, and is frequently used to protect and preserve soft drinks and meats.

MEDICAL

Citric acid is used to help kill harmful bacteria and infections on the skin’s surface, which are common in diabetics, the elderly, and smokers. Citric acid can also be combined with sodium citrate and potassium citrate to help prevent gout attacks bylowering acid levels in the urine.

CITRIC ACID USAGE

- COSMETICS AND PERSONAL CARE PRODUCTS

Citric acid, as an ingredient in personal care products, can help to brighten skin, correct dark spots, and minimize fine lines. Citric acid and its salts may also be used in hairsprays, deodorant and body sprays.

- CLEANING PRODUCTS

Citric acid can assist in the removal of hard water buildup on dishes and glassware. It can also be used to remove coffee and tea stains, as well as yellowing/browning and water and urine stains.

INDUSTRIAL PRODUCTION OF CITRIC ACID

Fermentation is the most economical and widely used methods for synthesis of citric acid.

The industrial citric acid production can be carried in three different ways: SURFACE FERMENTATION, SUBMERGED FERMENTATION, SOLID STATE FERMENTATION.

1.SURFACE FERMENTATION

| Surface fermentation is a stationary batch fermentation process that begins the CA fermentation process and lasts 8 to 12 days. It is carried out in fermentation chambers with a number of trays arranged in stainless steel shelves. On those trays, fungal mycelium grows on the surface of the medium. After sterilizing the fermentation medium in trays, it is inoculated with spore suspension and incubated for 24 hours at 28-30°C. Germination of spores began with a drop in medium pH from 6.0-6.5 to 1.5-2.0. A large amount of heat is generated during fermentation in this process, which is controlled by proper aeration. In concentrations greater than 10%, the CO2 produced during the fermentation process would inhibit the production of CA. Because the chamber must be effectively ventilated, the fermentation chambers have an effective air circulation system that passes over the medium surface through a bacteriological filter to control humidity and temperature through evaporative cooling. |

2.SUBMERGED FERMENTATION

| The broth medium inside the nutrient substratum is liquid during the submerged fermentation process, allowing the organism to grow throughout the broth medium. Fermentation occurs in bioreactors and takes 5-12 days to complete. After 1 to 2 days of inoculation, the organism grows as pellets of approximately 0.5 cm diameter suspended freely in the medium. As a result, the organism with a large contact surface area can absorb nutrients and oxygen. High-velocity air is introduced into the vessel, and agitation equipment mixes and breaks up the air bubbles to increase oxygen levels. The carbon source present are decomposed anaerobic or partially anaerobically by microorganisms present in the medium. |

3.SOLID STATE FERMENTATION

| Microorganisms are grown in a low-water-containing insoluble material that serves as both physical support and a source of nutrients in solid-state fermentation. The substrate used in solid-state fermentation is solid and moistened to about 70% moisture, the pH is between 4.5 and 6.0, and the temperature is between 28-30°C. The procedure takes about 4-5 days to complete. |

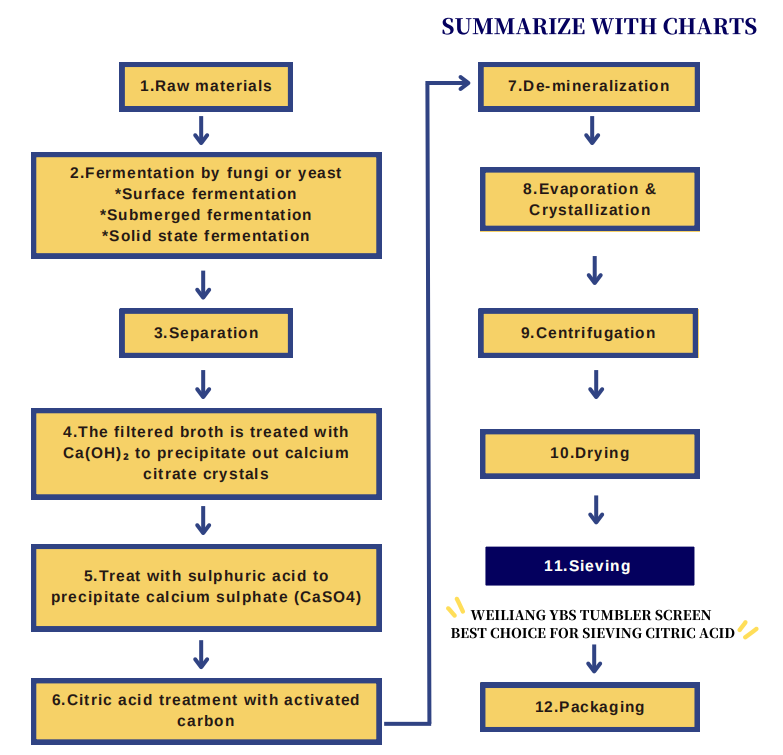

Citric acid production flow:

Raw materials—Fermentation by fungi or yeast—Separation—Filtered broth is treated with Ca(OH)₂ to precipitate out calcium citrate crystals—Treat with sulphuric acid to precipitate calcium sulphate (CaSO4)—Citric acid treatment with activated carbon—De-mineralization—Evaporation & Crystallization—Centrifugation—Drying—Sieving—Packaging

HOW TO SIEVE CITRIC ACID EFFECTIVELY

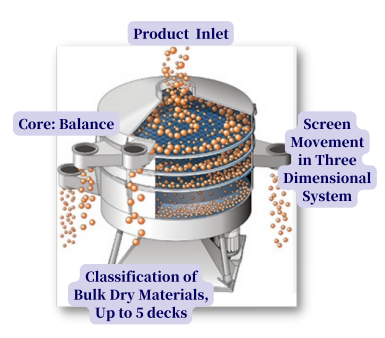

WEILIANG YBS tumbler screen simulates a form of simple hand sieving motion, which are used for classification of bulk dry materials for products such as chemicals, food, mining, pharmaceuticals, plastics and feed etc.. The core of the tumbler screen is the patented three-dimensional adjustment system that enables screening of fine & ultra-fine particles with ease.

The uniqueness of WEILIANG YBS Tumbler Screen allows screening material to move in a spiral direction on the mesh, enabling the material stay on the screen surface for a longer time & this in return gives precise screening & grading.

OUR CASES

Material: Citric acid

Sieving demand: Separation into different sizes

Model: YBS-2000 / YBS-2600

Mesh size: Range from 10 to 70 mesh

- In sieving citric acid, the YBS TUMBLER SCREEN is gradually replacing the S49 vibrating screen because of its high precision and large capacity.

- One of our customer, ENSIGN, is a large enterprise which specializes in the production of citric acid series products. Weiliang, an indispensable partner of Ensign. WEILIANG YBS TUMBLER SCREEN plays an important role for Ensign to produce high quality citric acid series products. More than 60 units have been used in the production line.

- Weiliang has worked with more than half of the major Chinese citric acid manufacturers, which has extensive experience for sieving CA. Weiliang technology will adjust ERT parameters based on the characteristics of specific citric acid types to meet the screening needs, received positive feedback from our customers.