Introduction

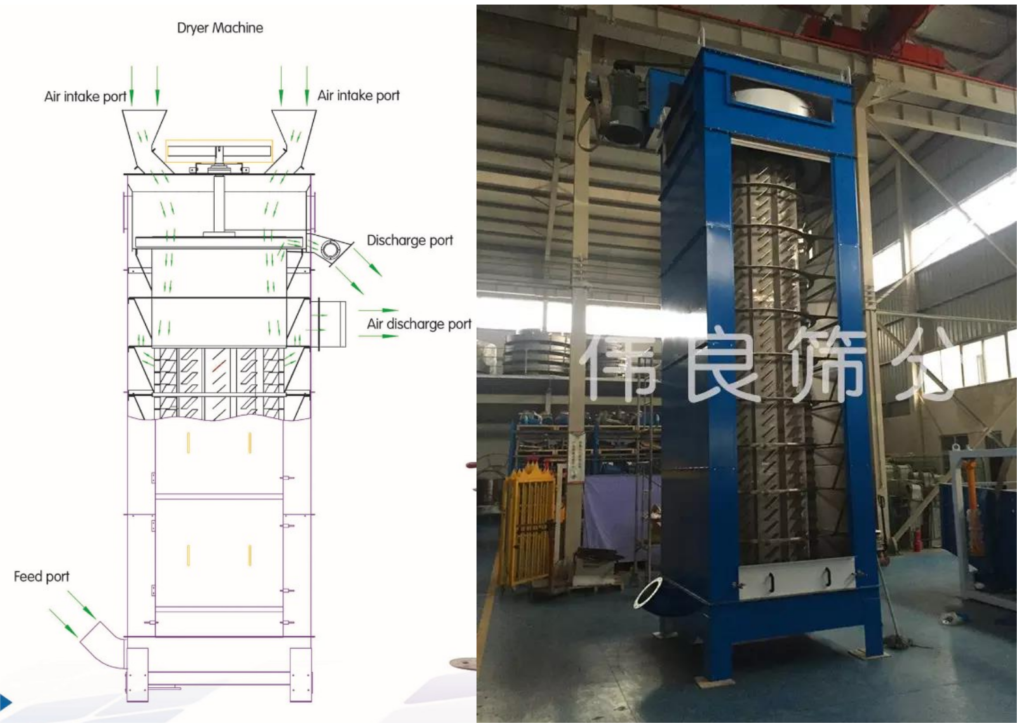

The WLG Dryer Machine separates pelletized EPS from water slurries in a continuous operation. Products can be discharged from the outlet on the top.

The whole drying process takes only a few seconds, the final material will be discharged quickly, and the surface moisture content of the EPS pellects after dried is as low as 0.05%, which is dry enough to go directly to packaging system or storage.

Check this video link of testing EPS dryer in our factory: https://youtu.be/LHNpLJYrXog

The WLG Dryer Machine protects against product contamination, reduces maintenance intervals, and maximizes dryer output.

WLD Dryer

Principles

Final drying is accomplished by spinning off the moisture through the centrifugal action of the vertical rotor located in the center of the dryer. The rotor consists of impeller blades extending from the bottom to the top of the WLG Dryer. As the water is removed, pellets are carried to the top by the rotating blades. Our tubular solid rotor design and solid casing (screen) selection allows the dryer to control the counter- current air flow through the pellets with none of it passing into the rotor and bypassing the pellets. This significantly improves the efficiency of pellets dryness. Solid casings are installed near the top of the rotor to increase the air contact time. The final EPS pellets are then discharged at the top.

Features

- Unitized tubular rotor construction

- Higher drying capacity

- Easy access for screen changes

- Longer service life

- 12 Month Warranty

- Reduced downtime for major service

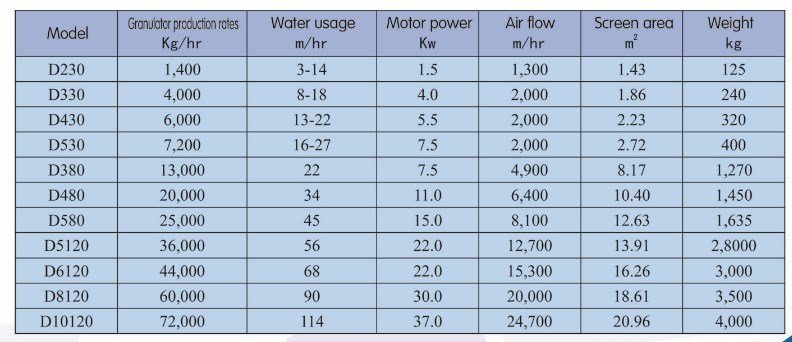

Technical Parameter

Our Story

One of our customers from Taiwan, who is one of the world largest EPS producers. At present, they have factories in Taiwan, Ningbo, Jiangyin, Karamay, Panjin, Zhangjiagang, and Yan’an, with a total production capacity of 2.33 million tons, occupying more than 45% of the EPS global market share.

There are three process of EPS production in their factories, Reaction, Dewatering & Screening and Packaging. They chose Weiliang as an integral part of their production line.

In the ten years of our cooperation, more than 10 Dryer Machine and 100 Tumbler Screen have been sold to their branch factories.

Installation Reference

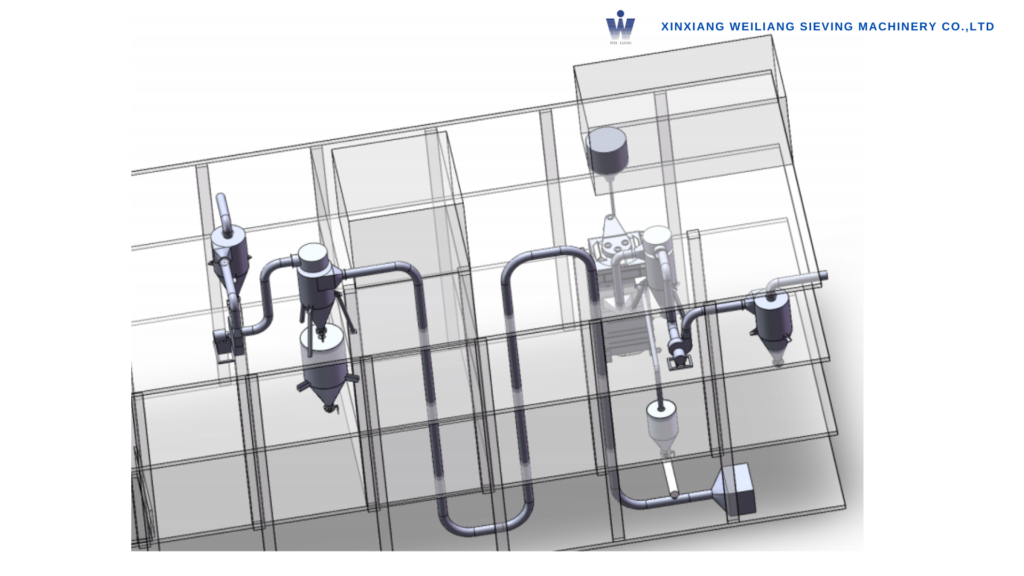

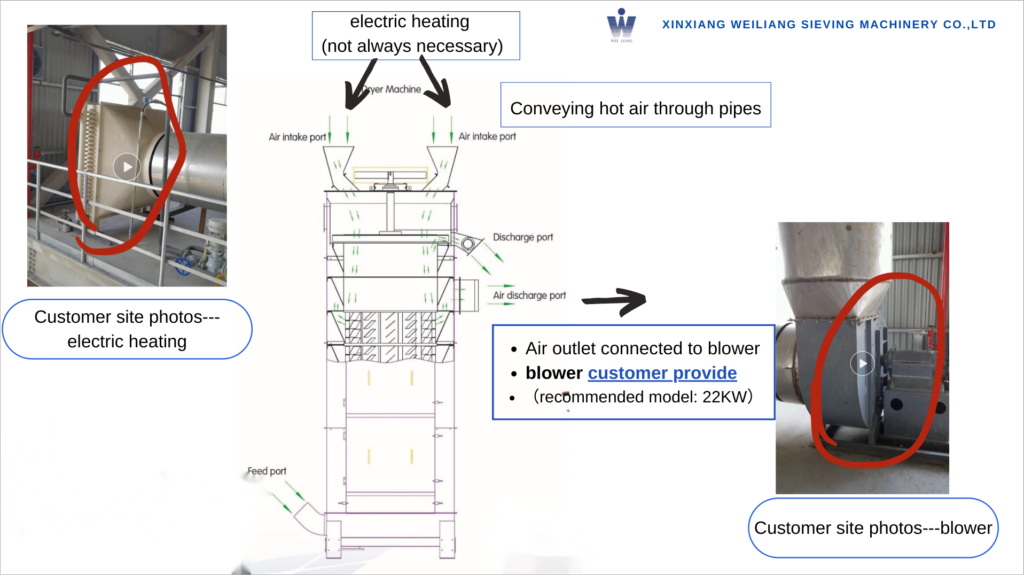

We only supply stand-alone EPS dryer machines, heaters, blowers, connecting pipes are not included.

The production line design for each customer is different. The following instructions are only as an example for reference. Customers need to design the production line according to their own needs.

Introduction

The average temperature in Delhi is 18-31 ℃ degrees throughout the year, and the average temperature in winter is 9-24℃ degrees.

Delhi weather is 11 months Humidity Levels are <30%, and one month is above >50%

Based on these data, we recommend that the heating system on top of the machine is not required.

On-site Photos

Tips

For screening dry EPS, Tumbler screen would be a nice choice, please contact us for more details about YBS tumbler screen.

EPS screener